Export Compliance

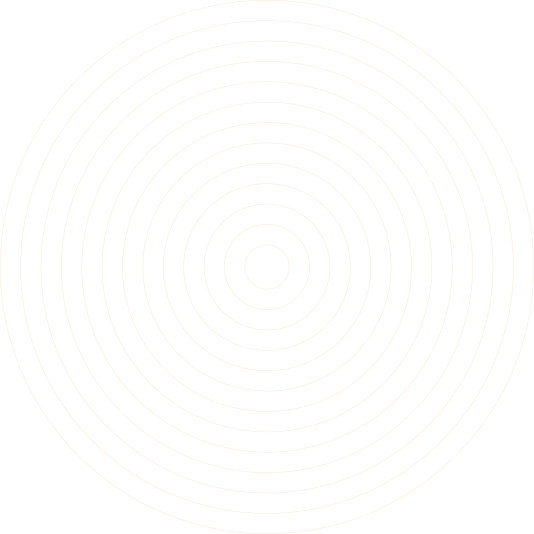

Export ComplianceVista-Suite Enterprise comes complete with an export compliance toolkit to eliminate manual and fragmented processes. Compliance-critical documents like end-use Certificates and export licenses are stored within the company or part records for immediate access. Automated denied party screening runs in real time through a premium Descartes Visual Compliance integration, with audit trails and compliance holds applied to flagged inbound request for quotes (RFQs). Users can assign and track part-level classifications, including ECCN, HTS, ITAR, and more, while system-generated labels, invoices, and shipping documents embed critical customs-related information. Alerts for expiring documents, inputs for tracking customer export licenses, and proactive classification notifications reinforce internal controls. Structured note systems and note-based reporting ensure continuity and accountability across your compliance workflows.

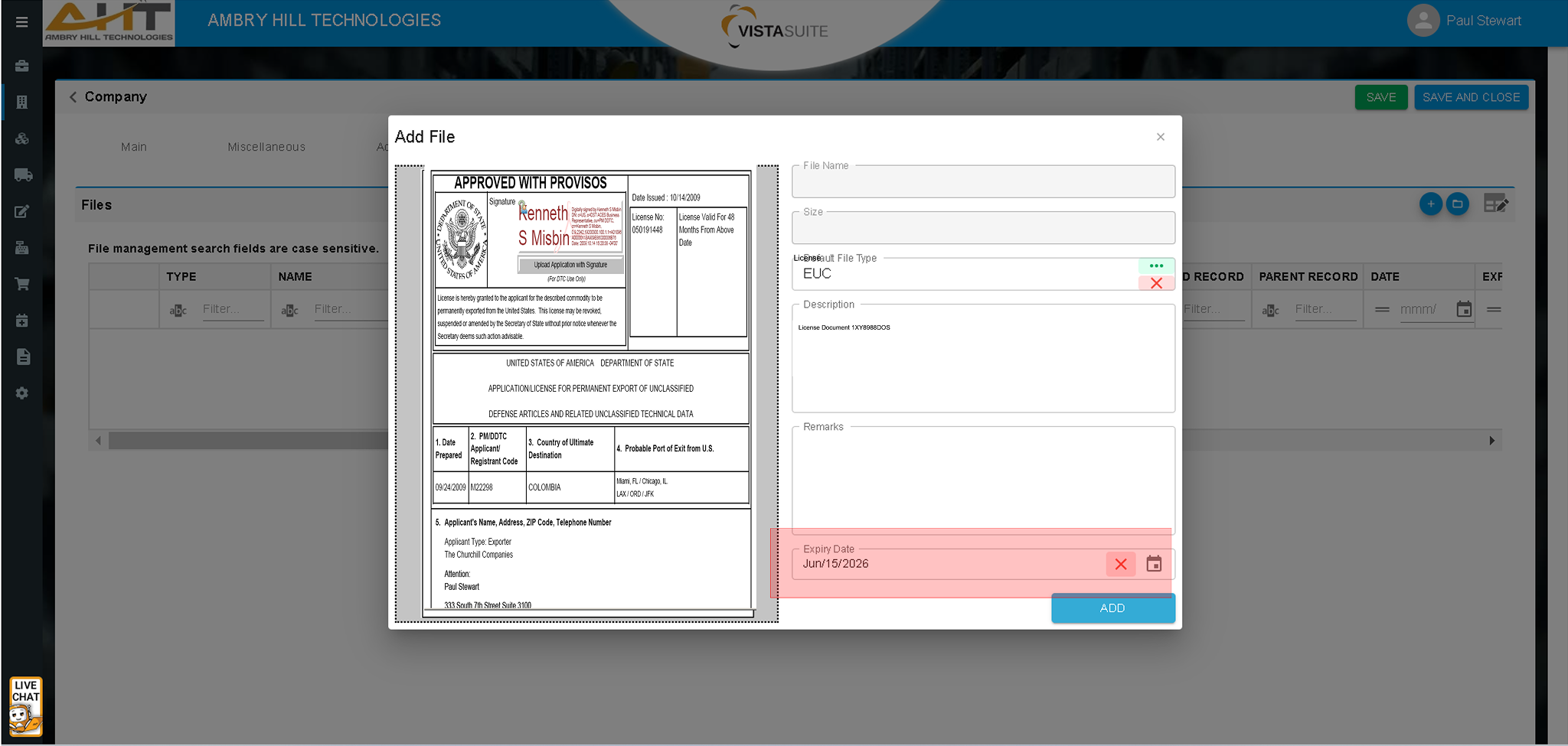

Store scanned End Use Certificates (EUCs) and other vital compliance documentation directly in each company record. Unlike many legacy ERPs that require separate document storage or manual cross-referencing, this centralized approach guarantees quick retrieval for audits and due diligence.

Attach and easily retrieve licenses and other critical documentation at the company or part levels throughout the system. Eliminate manual or spreadsheet-based tracking with a filing system designed for high-performing teams.

- Company Edit Showing Export Compliance Buttons.png)

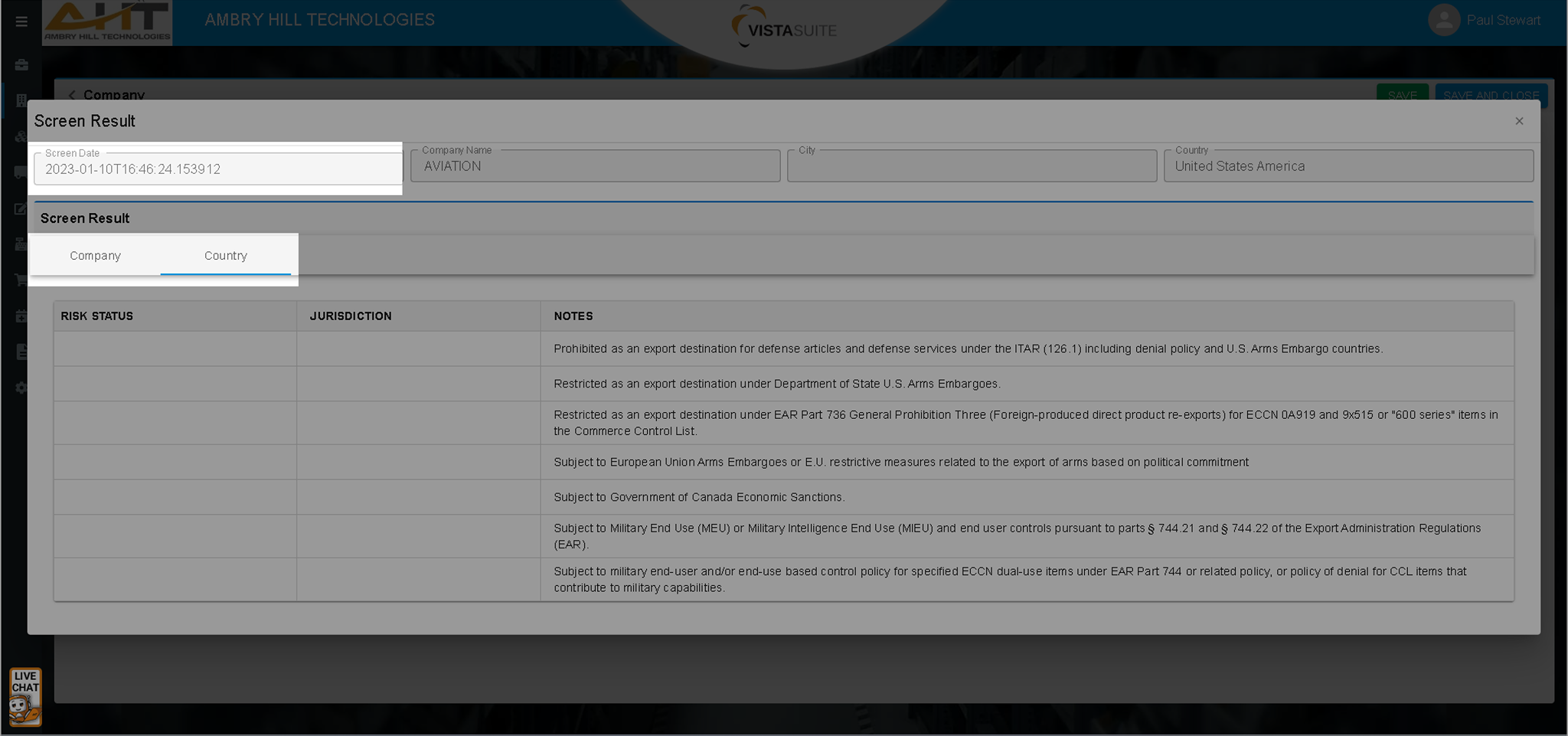

Automatic inbound RFQ screening of companies and individuals against up-to-date global lists through a separate Descartes eCustoms integration. When your only option is manual screening, you risk compliance gaps. That’s why Vista-Suite automates and documents denied party screening for proactive due diligence.

Screening - RPS Manual Screening.png)

Manually screening every company and individual was the norm, but with Vista-Suite Enterprise, now it’s the exception. An integrated screening interface is available for scenarios that require manual checks.

Every screening event is logged with time and date stamps within each company record to provide permanent, verifiable compliance screening history.

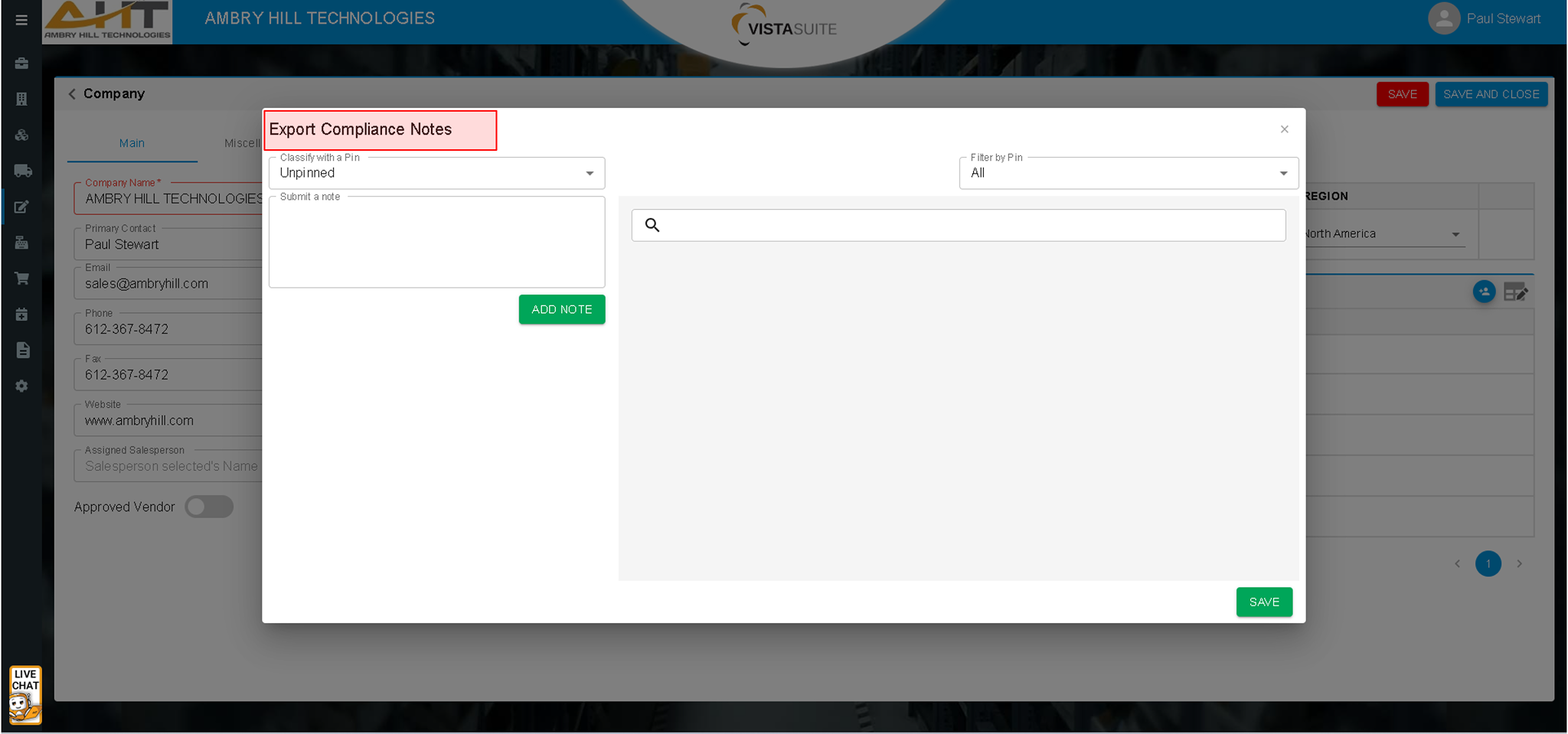

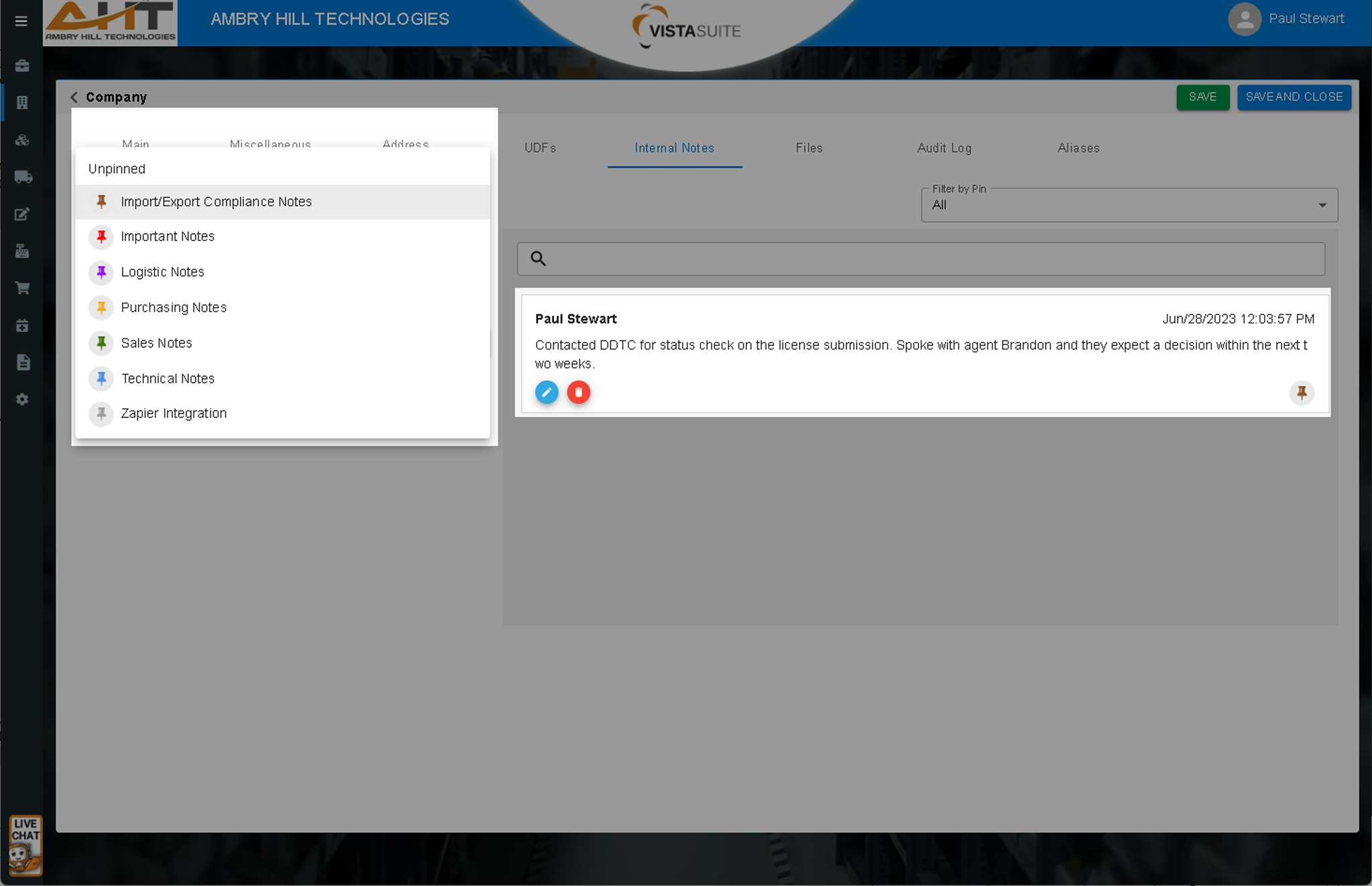

System-wide, categorized (pinned) note-taking on screening decisions and findings. Unlike basic note fields in most legacy platforms, Vista-Suite enables structured and auditable compliance record-keeping.

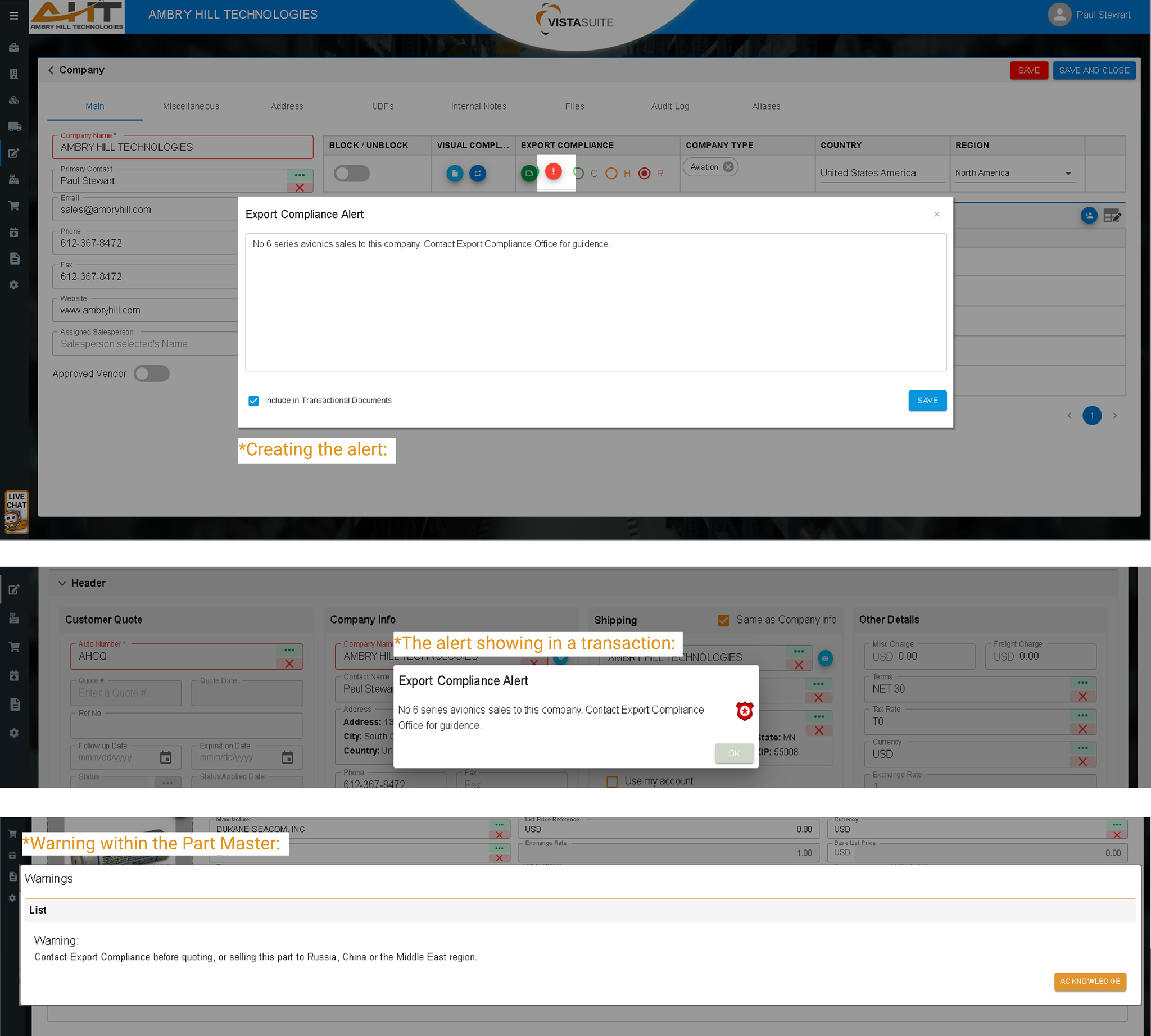

Presents actionable, user-acknowledged compliance warnings at key transaction points (i.e. initiating quotes, sales orders, etc.) to proactively prevent compliance mistakes that could easily be missed in older, less interactive systems.

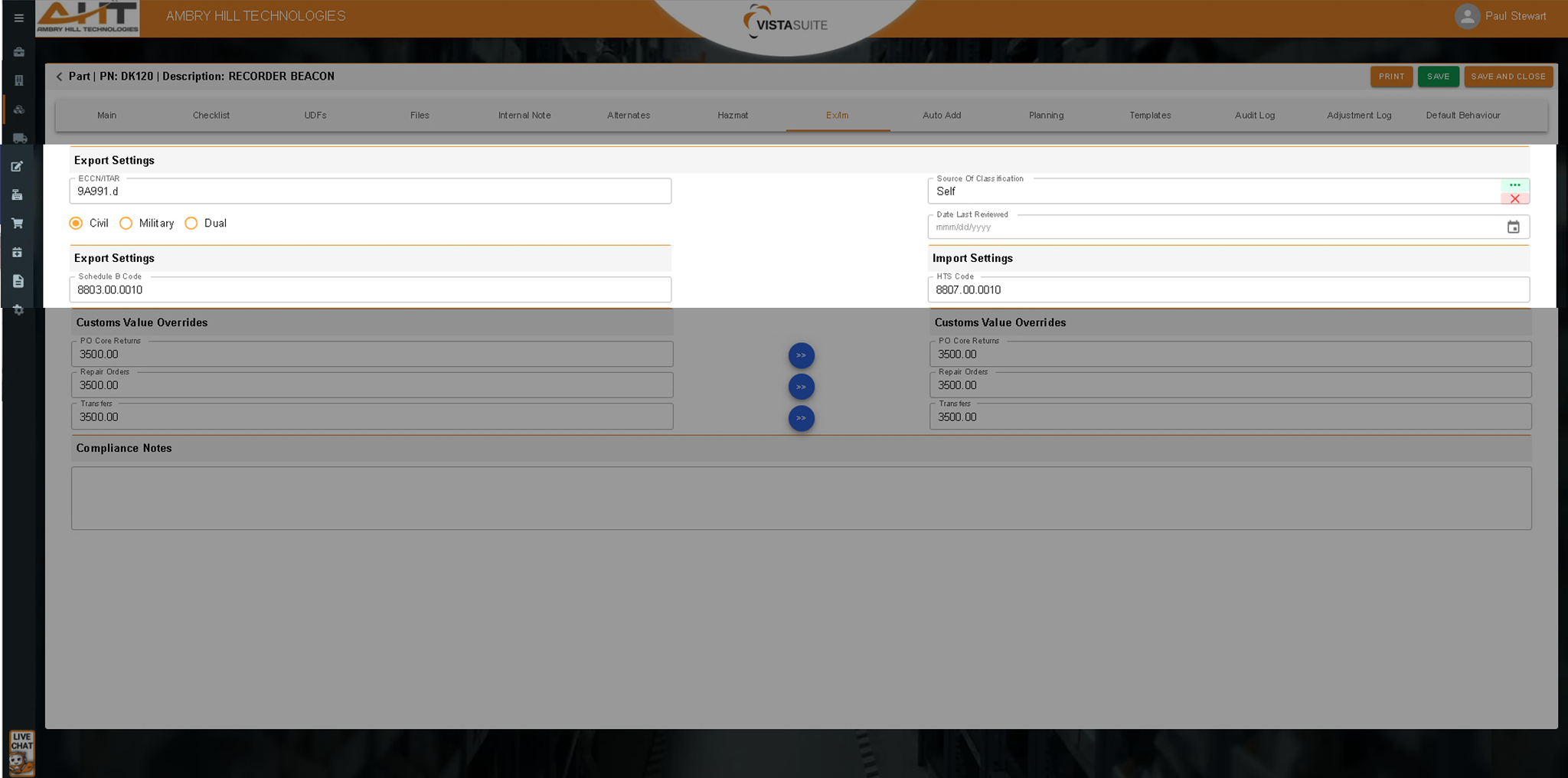

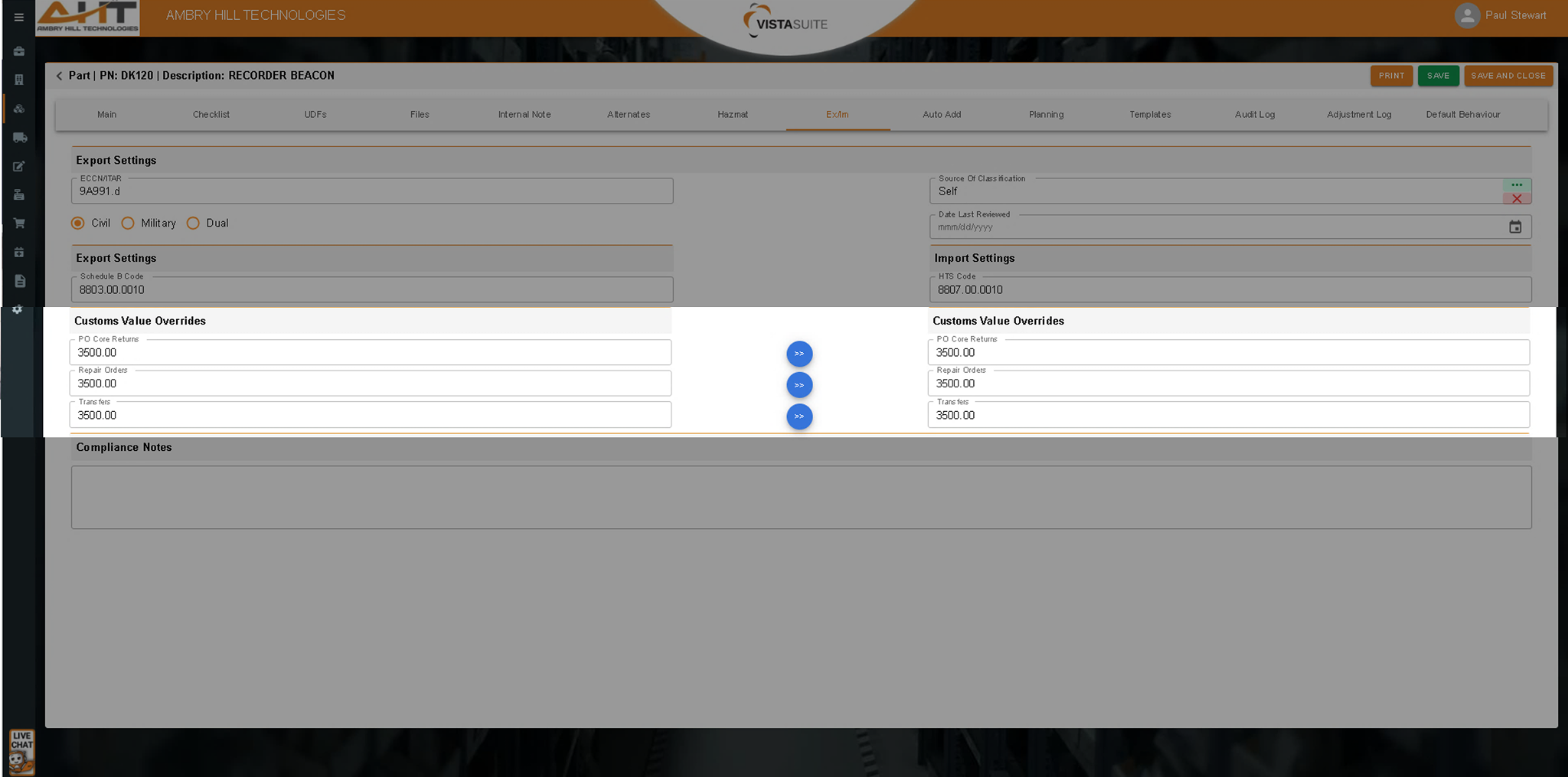

Purpose-built for international trade, fields in the part master record (ECCN, ITAR, Schedule B, HTS, etc.) support granular export/import control at the part level. This is far more flexible than the limited catalog fields typically found in other aviation ERP software, ensuring that classification data is quickly accessible where needed.

The customs value override defined in the Export/Import (Ex/Im) section of a part record is used only when a value is absent on a transaction while creating Logistics Order Shipments (LOS). Consider them as “fallback” values that can optionally be incorporated into your system documents using the system’s form designer.

Create, categorize, and date/time-stamp compliance notes across all transactions. This level of structured documentation is totally unique to Vista-Suite Enterprise. Attach files to a note, lock a note, search, filter on notes, and even run reports on different pin categories. Vista-Suite Enterprise's pinned note system is so powerful that some companies use it instead of a CRM. A dedicated compliance note area prevents mixing with general notes. This is a massive advantage for efficient team communication and compliance awareness.

Drag-and-drop the columns of information within a table/grid to align with your viewing needs. Export compliance fields can be arranged for maximum visibility, tailored to your specific process.

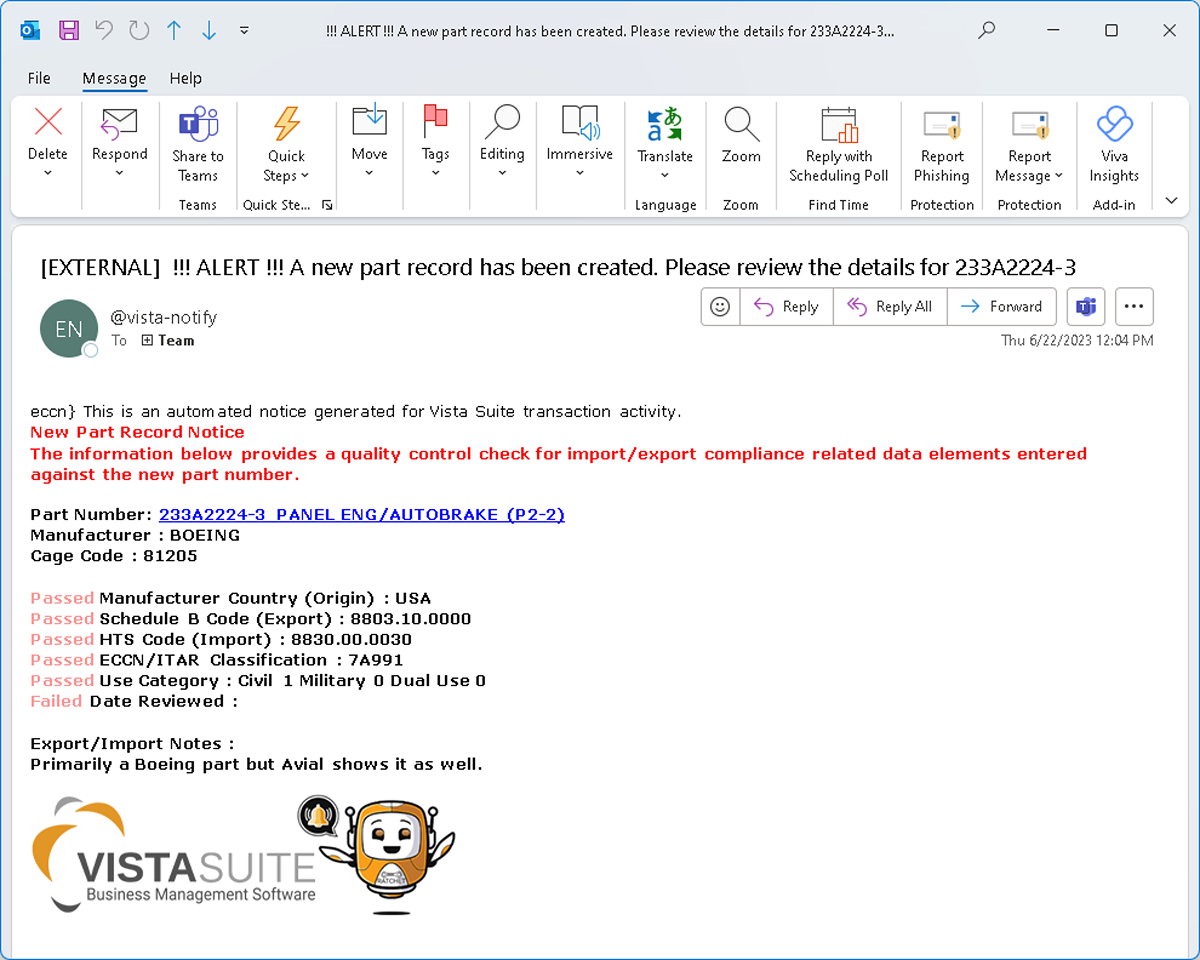

An automated email alert will be sent to your designated email notification recipient when new part numbers are added to Vista-Suite Enterprise, supporting proactive compliance workflows. Premium service add-on.

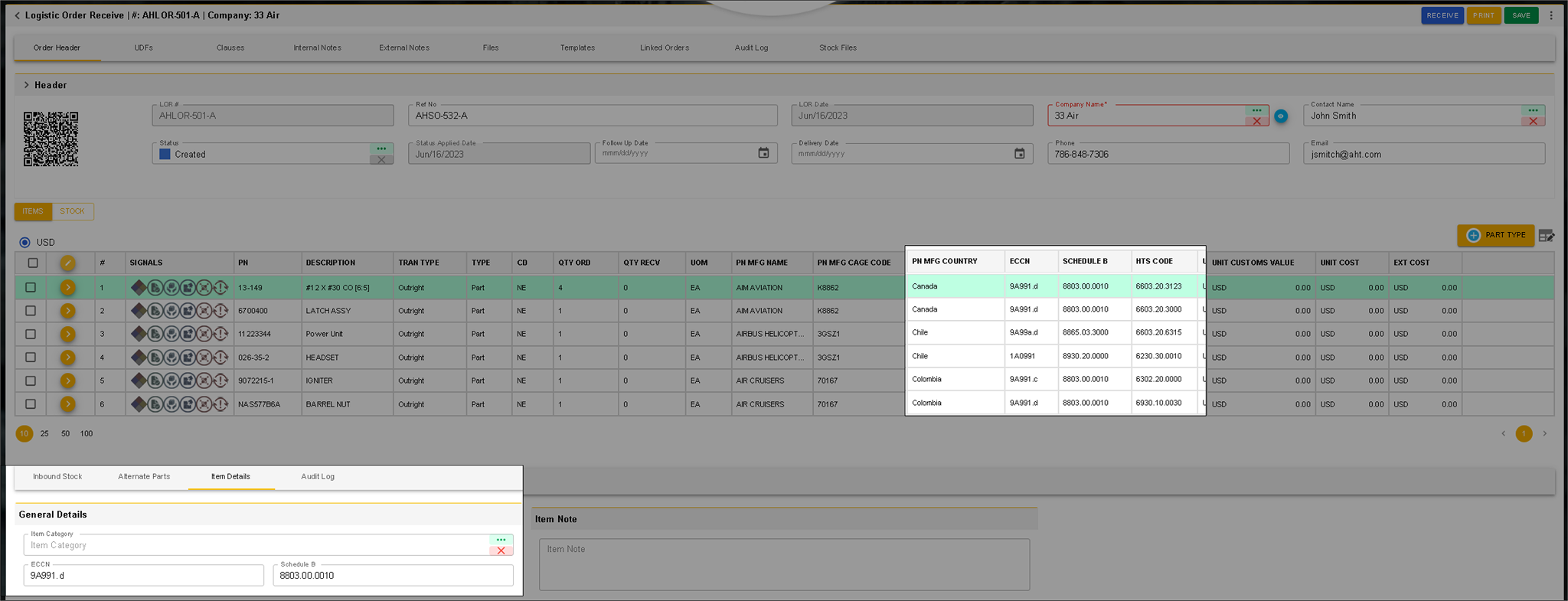

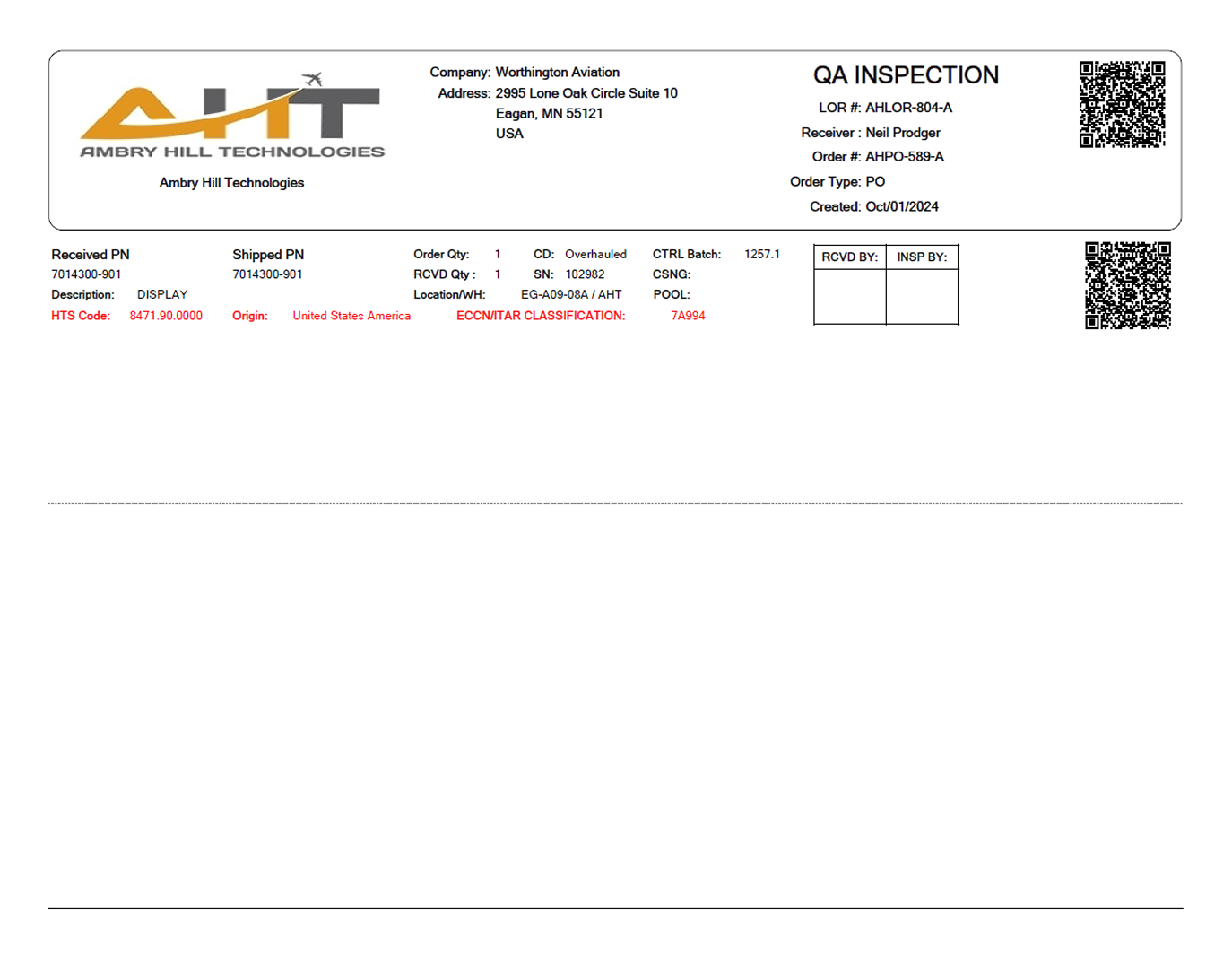

All compliance data (i.e. HTS, ECCN, origin, etc.) is shown on-screen and on printed LOR documents when receiving items. Convenience and speed come together to provide the essential information you require for speedy classification and compliance checks when receiving goods.

Maintain license details using adaptable, user-defined fields that can be reported, facilitating compliance workflows even without a separate and complicated license management module.

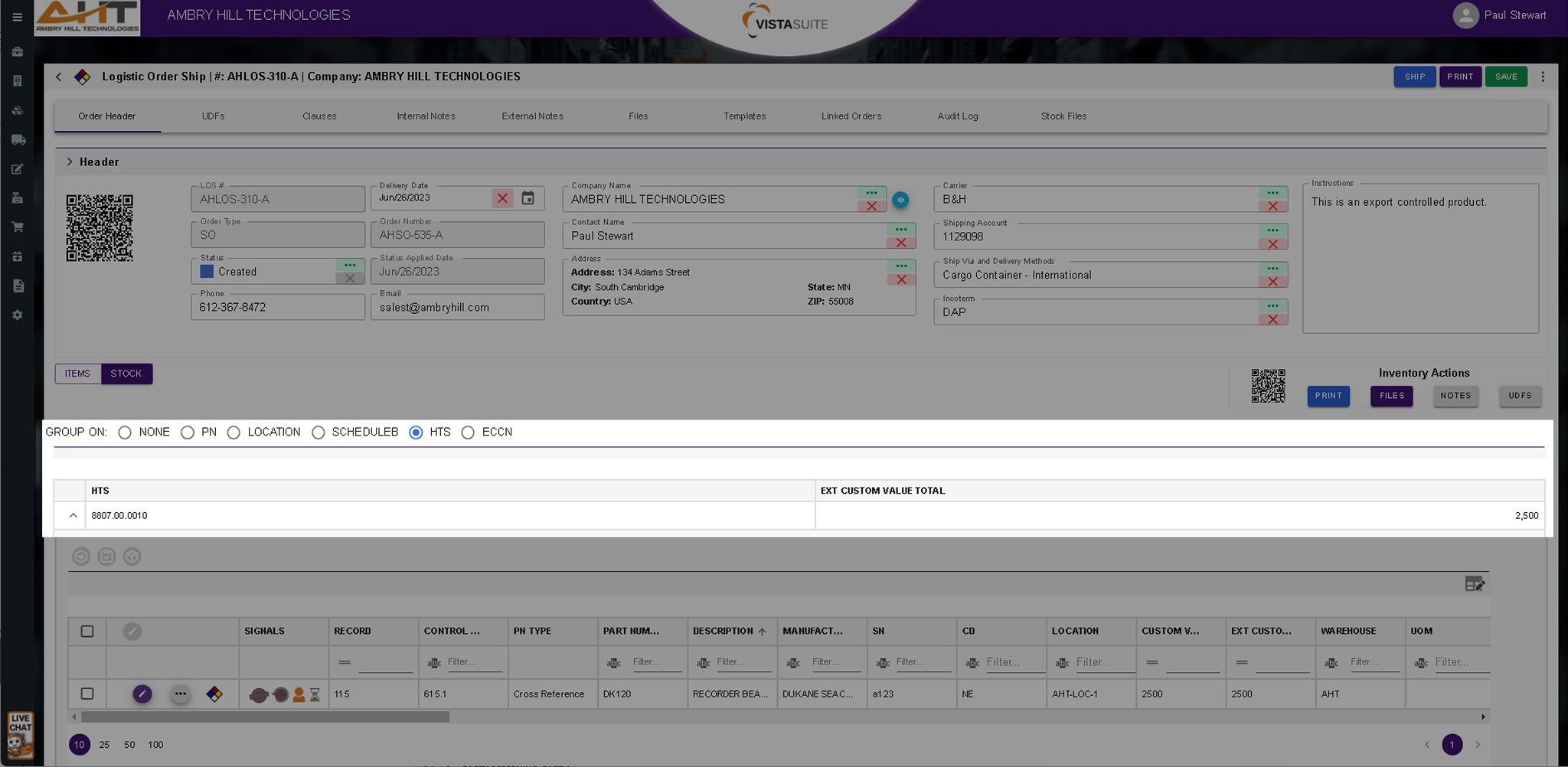

The Logistics Order Ship (LOS) transaction interface distinguishes between a general "items" view (representing the ordered or expected items) and a detailed "stock" view (representing the individual inventory records/serialized parts). If you toggle to the Stock View, you can quickly total your customs values by Part Number, Location, Schedule B, HTS, or ECCN codes. This makes filing for your Shipper’s Export Declaration (SED) quick and easy.

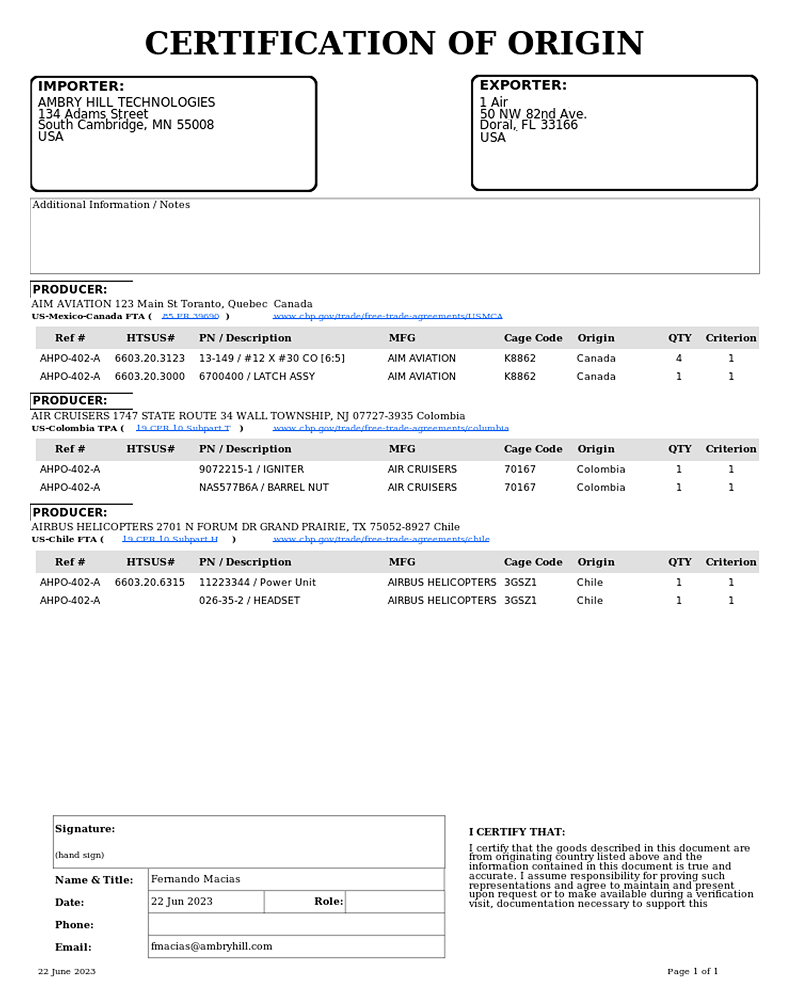

Certificate of Origin: When importing goods, it is often necessary to provide Customs with the Source of Origin, or Country, where the product was produced. Vista Suite offers a pre-built Certificate of Origin document found in the Logistics Order Receipt (LOR) application.

Quality Assurance Inspection Form: When importing goods, it is often necessary to provide Customs with the Source of Origin, or Country, where the product was produced. Vista Suite offers a pre-built Certificate of Origin document found in the Logistics Order Receipt (LOR) application.

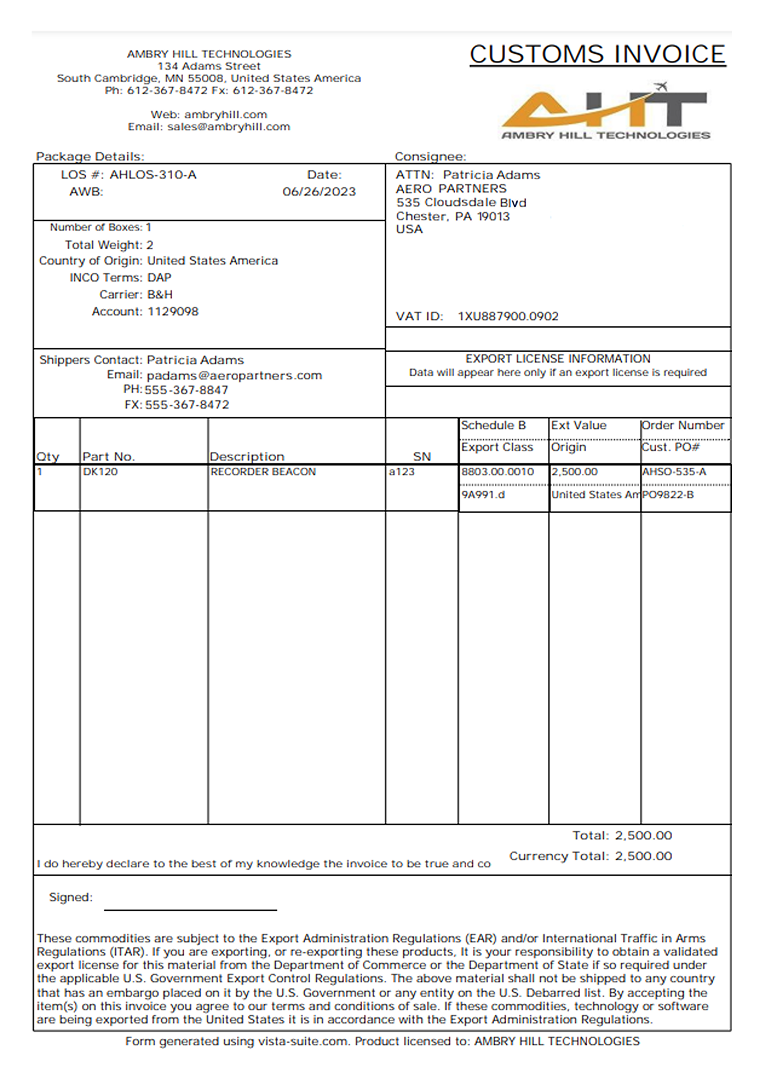

Customs Invoice Document: The Customs Invoice, generated by the Logistics Order Shipping (LOS) module, is a required document for international shipments. It provides customs authorities with all the necessary details to assess duties, taxes, and ensure the legal movement of goods across borders. This includes information such as item descriptions, quantities, declared value, country of origin, HTS codes, Incoterms, and full shipper and consignee details. The Vista-Suite Enterprise LOS system automatically pulls this data from the corresponding order, reducing manual entry and minimizing errors. By standardizing this critical document, the system helps shippers maintain compliance with global trade regulations and avoid delays in customs clearance.

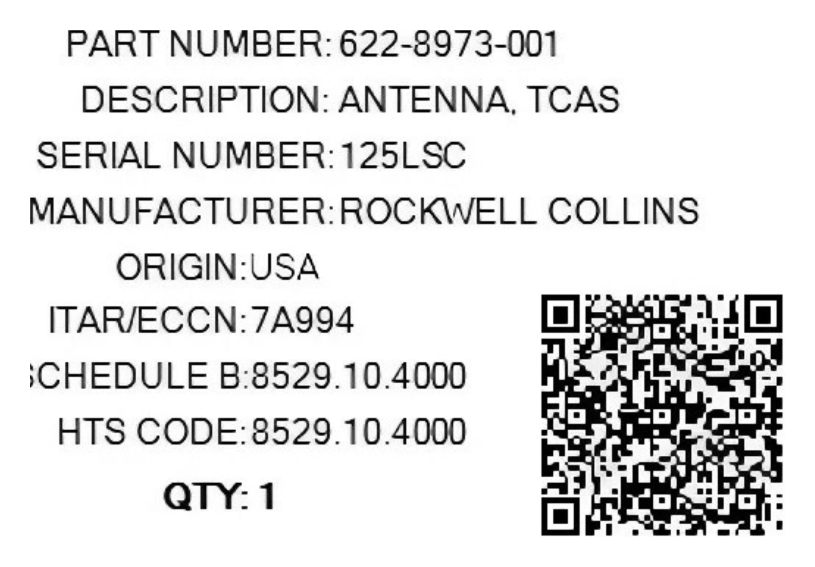

Shipping Label: Essential compliance information and manufacturer traceability are embedded into a single,

easy-to-read label. This isn’t a typical label; it’s a built-in quality and compliance tool that

enhances every shipment.

Unlike generic ERP-generated labels, this format includes critical export and customs data,

supports serialized inventory management, and includes QR codes to quickly retrieve the

corresponding LOS record through the Vista-Suite Enterprise mobile application.

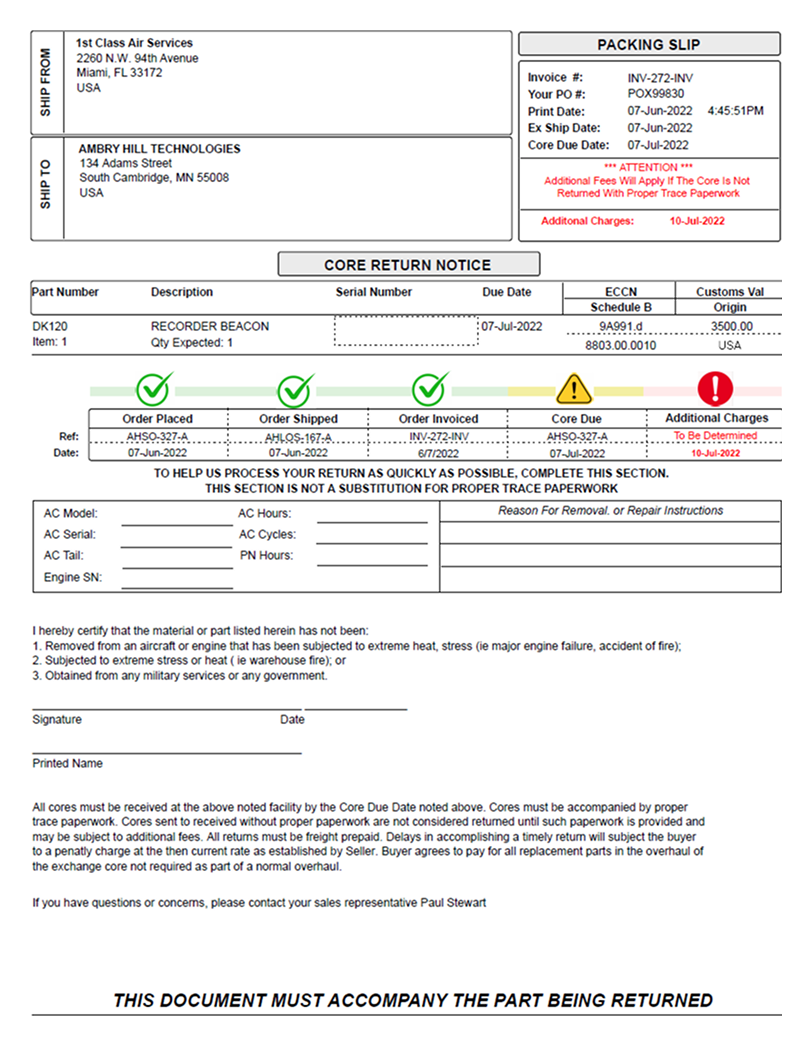

Core Return Pack Slip: The Core Return Pack Slip is a document generated by the Logistics Order Shipping (LOS) module to accompany the shipment of a part that requires a core return. It provides clear instructions and reference details for the recipient to return the used or repairable core component. Typically included in the outbound shipment, the slip stays with the new or overhauled part and serves as both a return authorization and tracking reference when the core is sent back. This document helps streamline the reverse logistics process, reduce delays in core returns, and ensure proper matching of returned cores to original transactions.

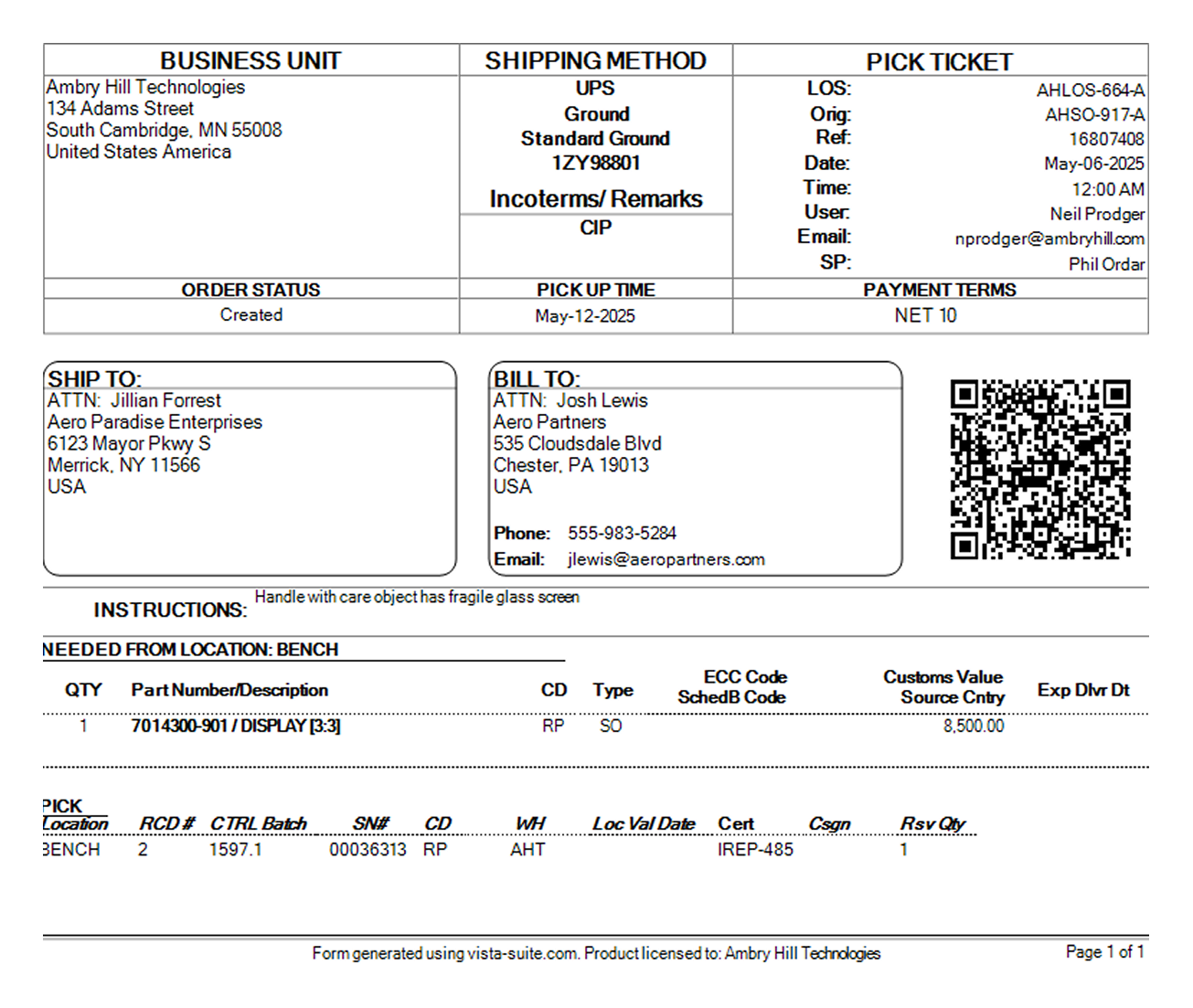

Pick Ticket: This internal document informs warehouse staff on which items to retrieve for order fulfillment. It clearly lists part numbers, quantities, and storage locations to streamline the picking process and reduce errors. A well-prepared pick ticket helps teams move faster and with greater confidence, especially when time-sensitive orders are in play.

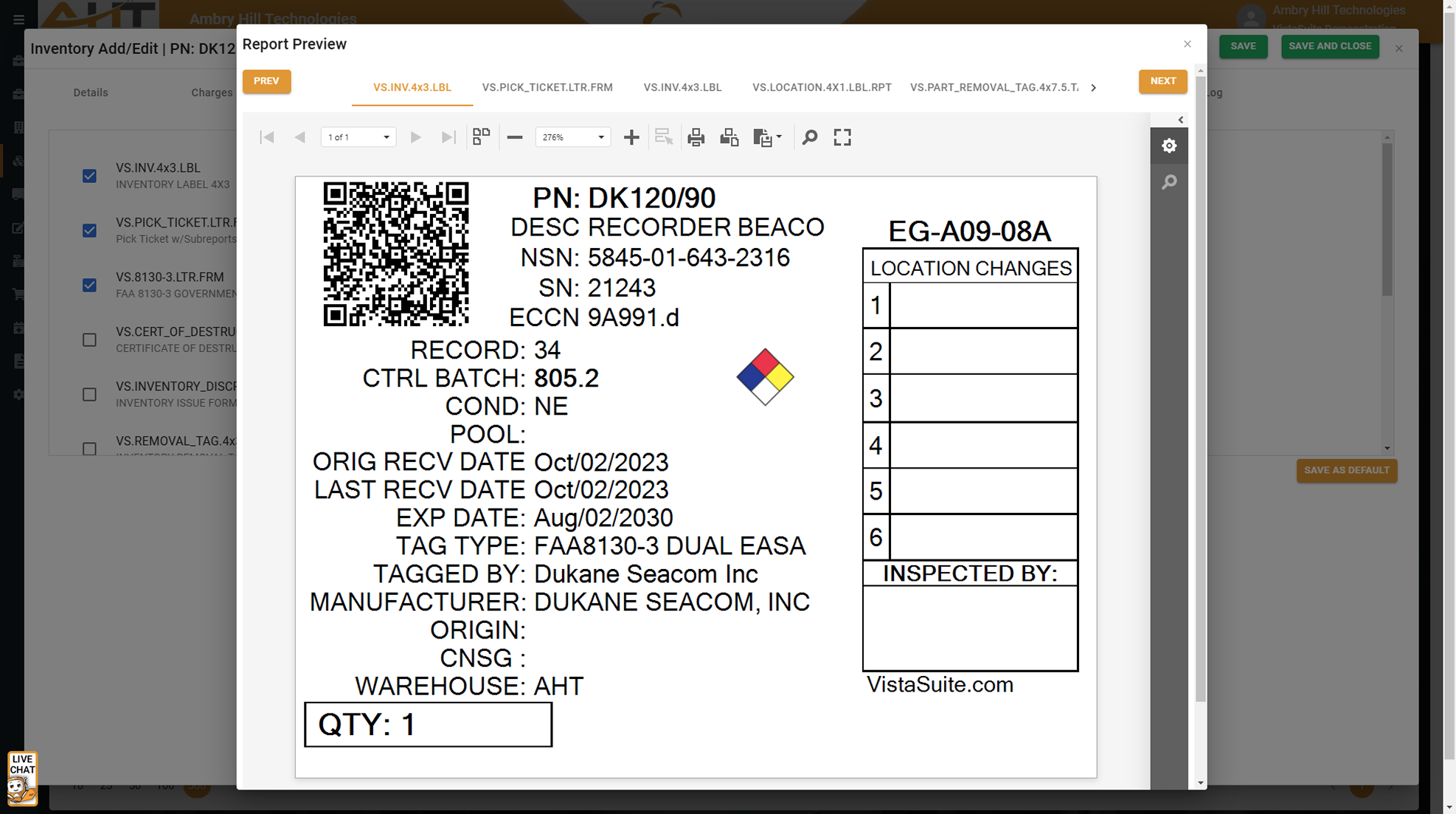

Detailed Inventory Label: The layout is both informative and useful; complete with QR code, unique signal icon, and space to keep track of location changes.

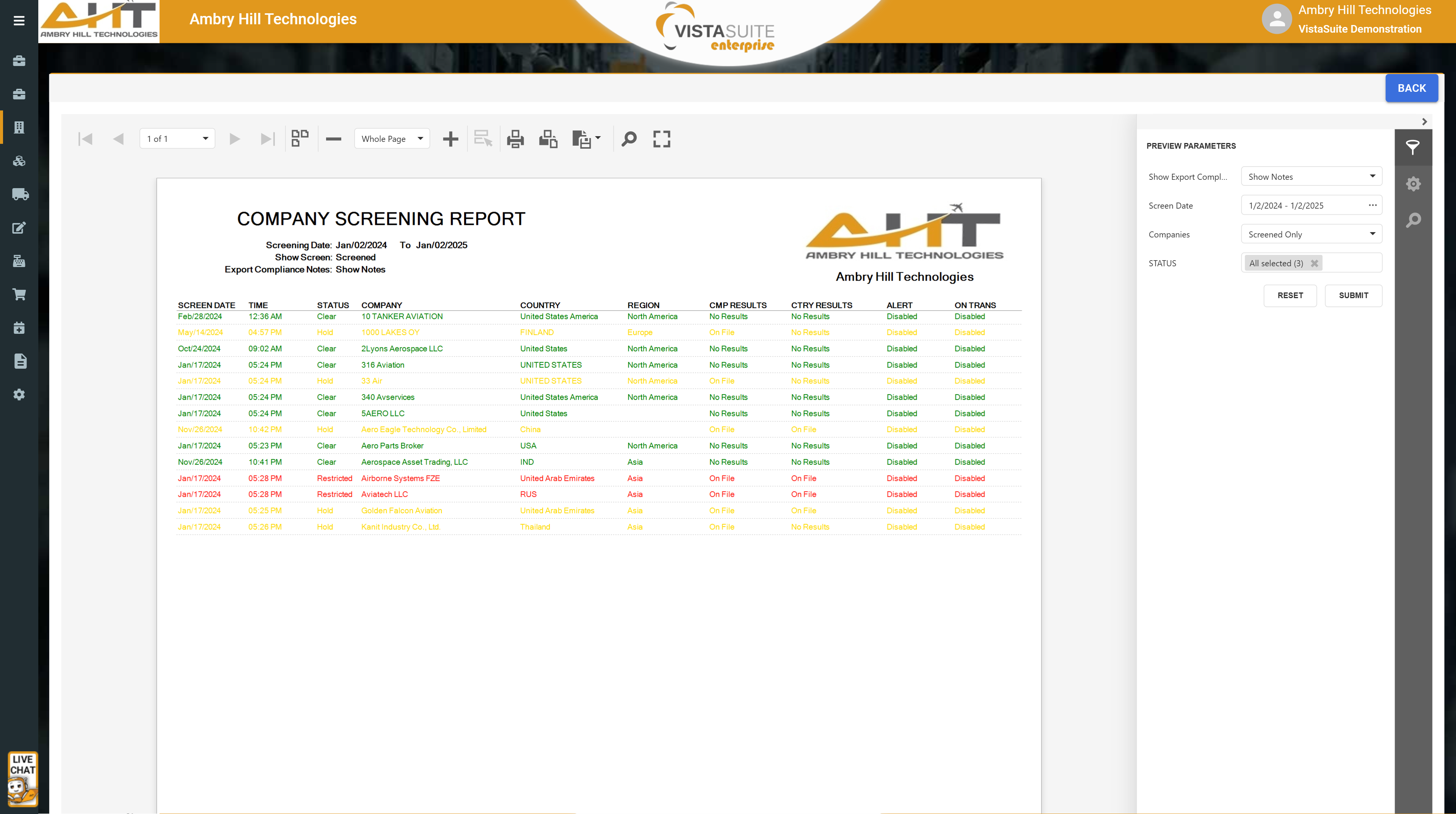

Filtered Company Screening Results: Displays the outcomes of compliance screenings for selected companies filtered on timeframe, company name, and record status. For best results, join Descartes separately to integrate and automate restricted party screening.

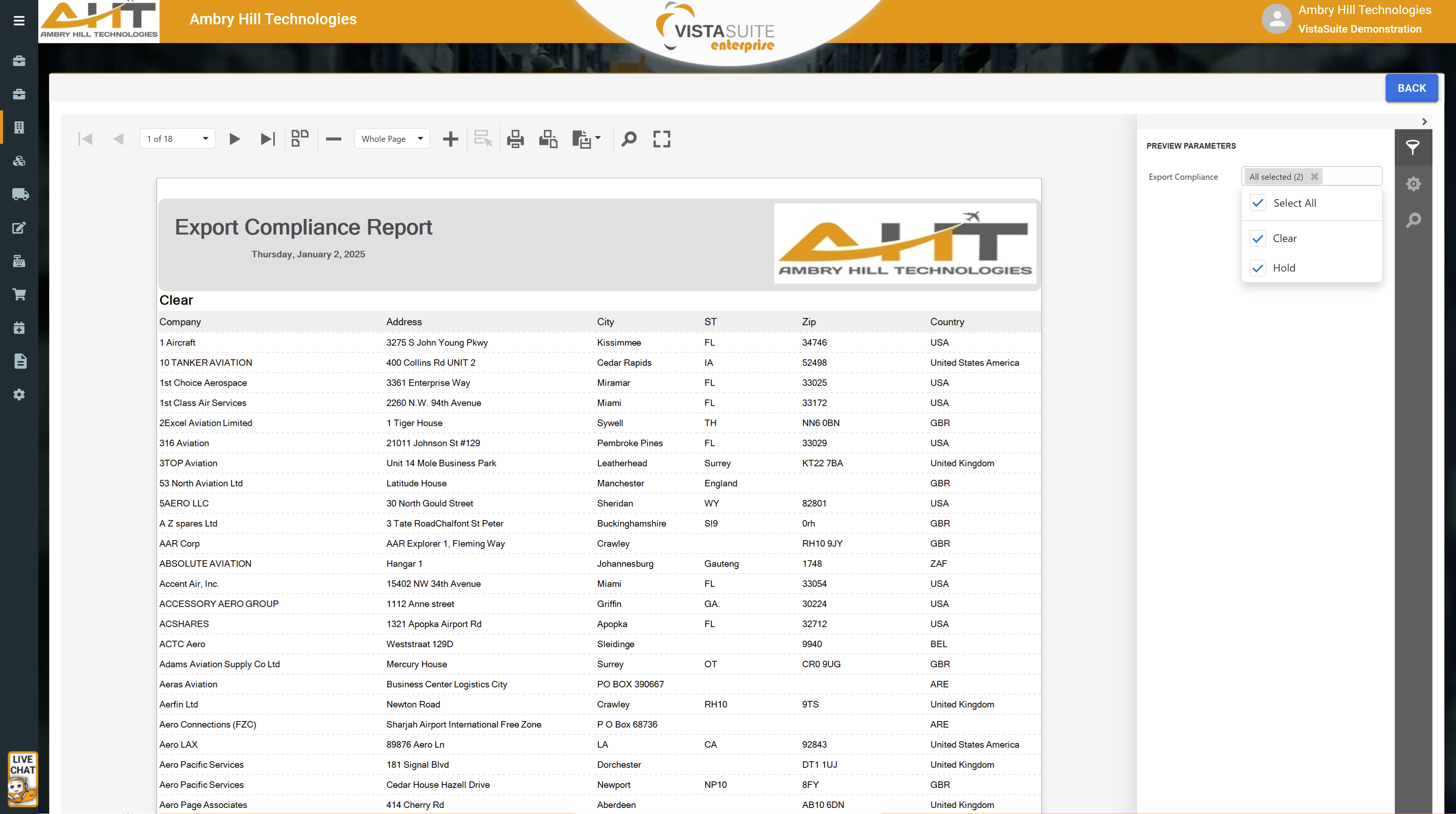

Export Compliance Status for All Companies: Sorts all companies according to the restricted party screening categories of clear, hold, or restricted. A separate Descartes membership is not required but is recommended to automate the screening process.

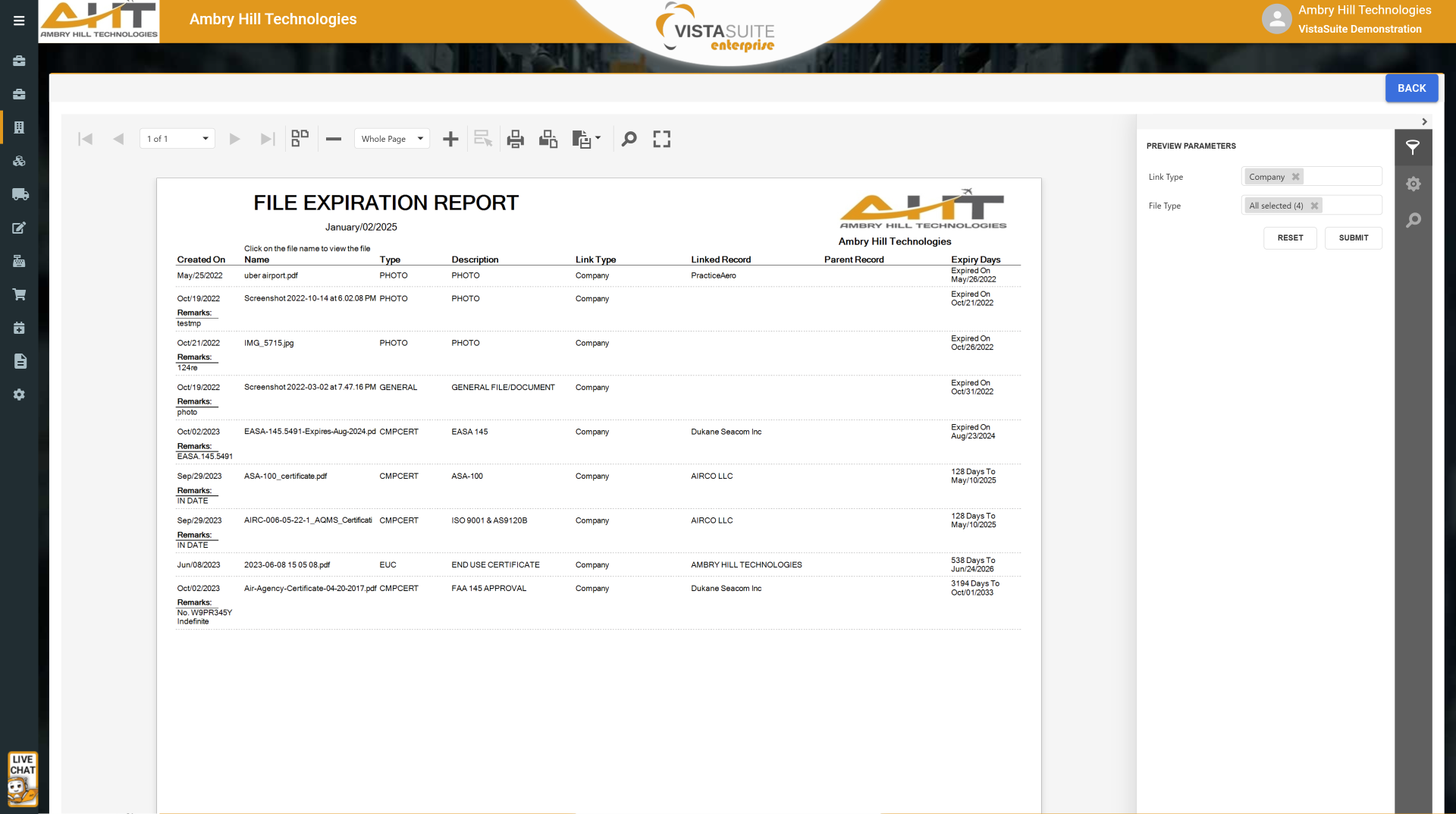

Expiring Documents Report: Lists files and documents based on expiration dates to determine ones requiring attention.

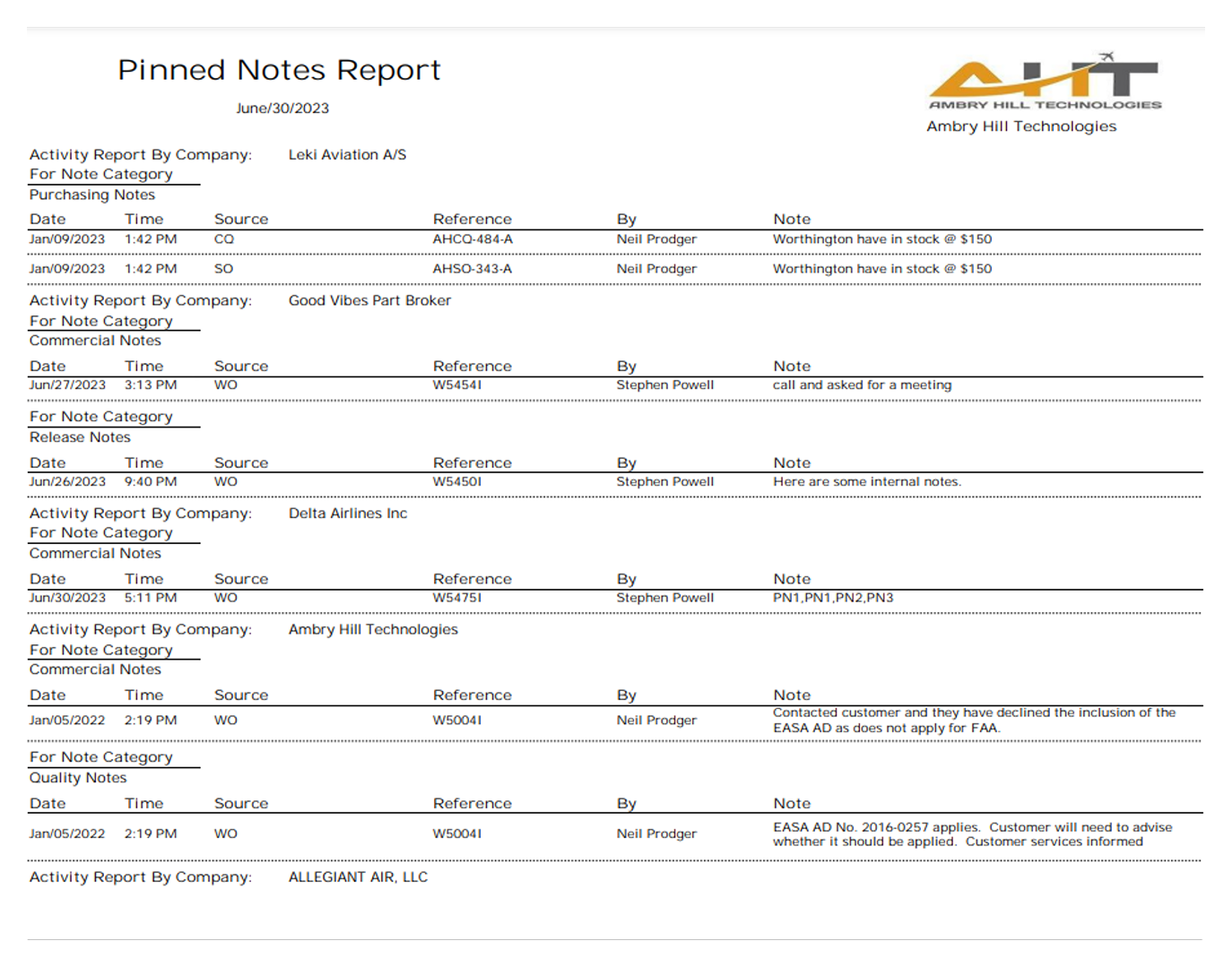

Pinned Notes Summary: A quick reference to all pinned notes across the system matching the specified search parameters.

When importing goods, it is often necessary to provide Customs with the Source of Origin, or Country, where the product was produced. Vista Suite offers a pre-built Certificate of Origin document found in the Logistics Order Receipt (LOR) application.

When importing goods, it is often necessary to provide Customs with the Source of Origin, or Country, where the product was produced. Vista Suite offers a pre-built Certificate of Origin document found in the Logistics Order Receipt (LOR) application.

The Customs Invoice, generated by the Logistics Order Shipping (LOS) module, is a required document for international shipments. It provides customs authorities with all the necessary details to assess duties, taxes, and ensure the legal movement of goods across borders. This includes information such as item descriptions, quantities, declared value, country of origin, HTS codes, Incoterms, and full shipper and consignee details. The Vista-Suite Enterprise LOS system automatically pulls this data from the corresponding order, reducing manual entry and minimizing errors. By standardizing this critical document, the system helps shippers maintain compliance with global trade regulations and avoid delays in customs clearance.

Essential compliance information and manufacturer traceability are embedded into a single,

easy-to-read label. This isn’t a typical label; it’s a built-in quality and compliance tool that

enhances every shipment.

Unlike generic ERP-generated labels, this format includes critical export and customs data,

supports serialized inventory management, and includes QR codes to quickly retrieve the

corresponding LOS record through the Vista-Suite Enterprise mobile application.

The Core Return Pack Slip is a document generated by the Logistics Order Shipping (LOS) module to accompany the shipment of a part that requires a core return. It provides clear instructions and reference details for the recipient to return the used or repairable core component. Typically included in the outbound shipment, the slip stays with the new or overhauled part and serves as both a return authorization and tracking reference when the core is sent back. This document helps streamline the reverse logistics process, reduce delays in core returns, and ensure proper matching of returned cores to original transactions.

This internal document informs warehouse staff on which items to retrieve for order fulfillment. It clearly lists part numbers, quantities, and storage locations to streamline the picking process and reduce errors. A well-prepared pick ticket helps teams move faster and with greater confidence, especially when time-sensitive orders are in play.

The layout is both informative and useful; complete with QR code, unique signal icon, and space to keep track of location changes.

Displays the outcomes of compliance screenings for selected companies filtered on timeframe, company name, and record status. For best results, join Descartes separately to integrate and automate restricted party screening.

Sorts all companies according to the restricted party screening categories of clear, hold, or restricted. A separate Descartes membership is not required but is recommended to automate the screening process.

Lists files and documents based on expiration dates to determine ones requiring attention.

A quick reference to all pinned notes across the system matching the specified search parameters.

We will respond to you within minutes