Shipping Management

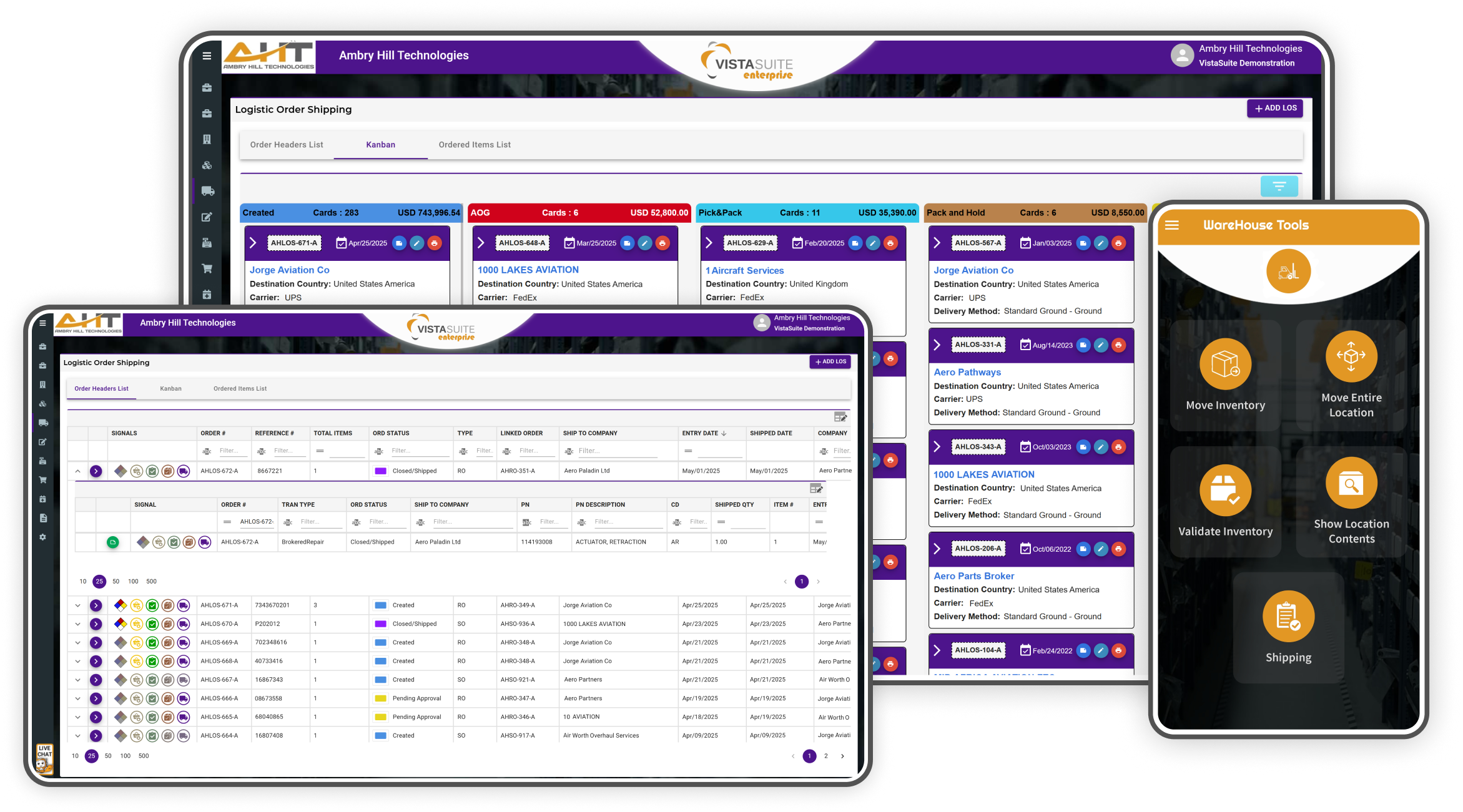

Shipping ManagementThe Vista-Suite Enterprise Logistics Order Shipping (LOS) application offers a highly detailed, fully integrated shipping workflow tailored to the demands of aviation logistics environments. LOS supports real-time data entry through a dedicated mobile app with QR-based photo capture, enabling accountability of packaging, condition, and part integrity at shipment. Users can manage serialized inventory across fulfillment stages with granular control, leverage system-wide visibility into pending and potential shipments, and configure shipment documents with precise clause, part, and compliance information, down to ECCN, INCO terms, traceability fields, and more. Built-in workflow enhancements include spreadsheet-style batch editing, audit logs at both item and header levels, and unique transaction URLs for quickly sharing records across teams. Whether working with alternates, core exchanges, partial shipments, or QA-driven export jobs, the LOS module consolidates critical shipping functions into a single interface designed for efficiency and operational continuity.

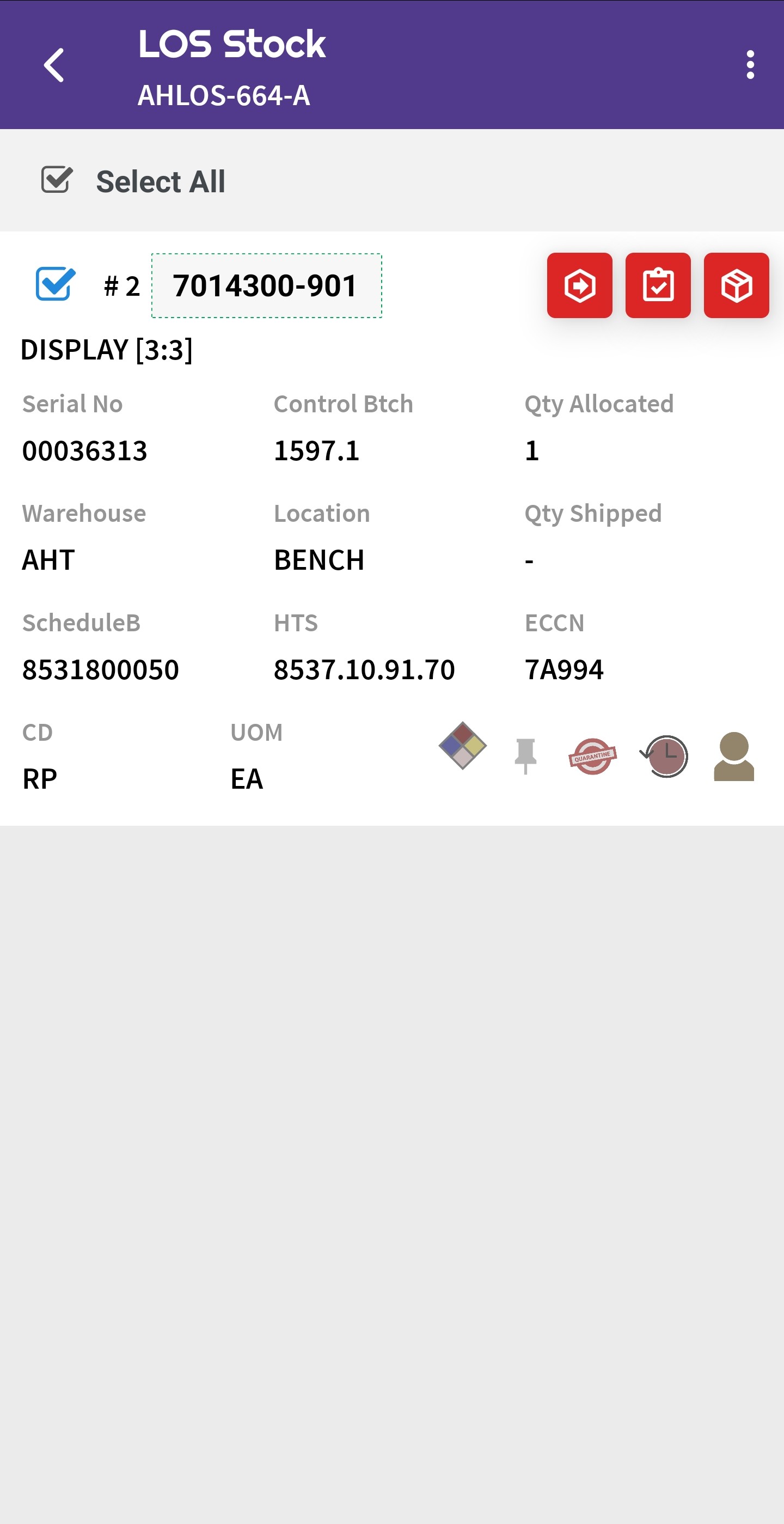

The Vista-Suite Enterprise LOS application enhances visibility of import and export information during the shipping process by prominently displaying Part Number, Manufacturer, Country of Origin, ECCN, Schedule B, and HTS Code. To support various shipping workflows, a QA Inspection form can be generated to clearly identify critical export classification details, including HTS Code and Origin. This document can also include sign-off capability, embedded QR codes, product images, linked notes, and part-specific icons to highlight hazmat or serialized status

Quality inspections are made easy by embedding relevant order instructions and compliance information directly into the QA document, eliminating the need for users to search separately for related transactions. Accurately evaluating outgoing items has never been easier.

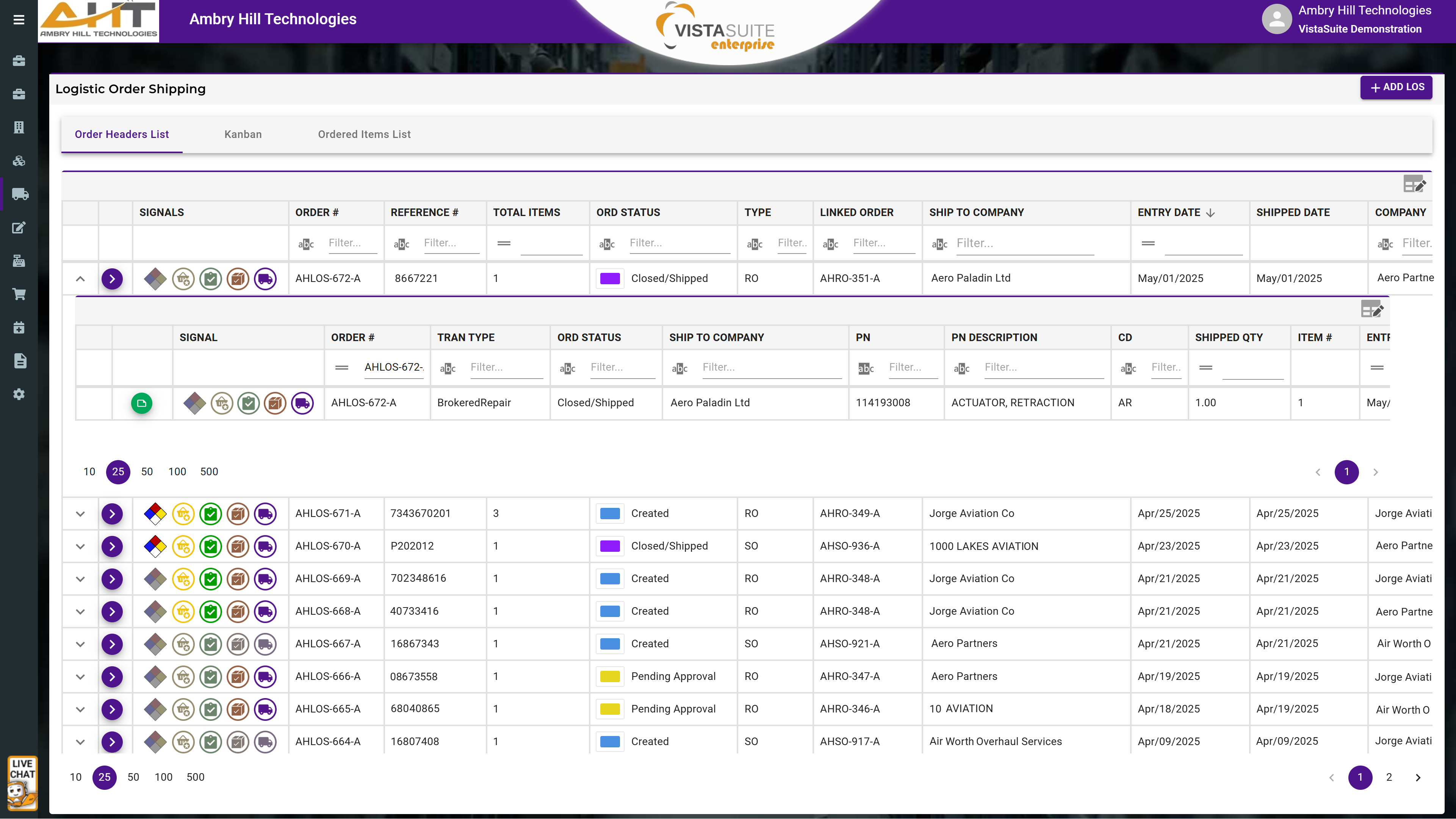

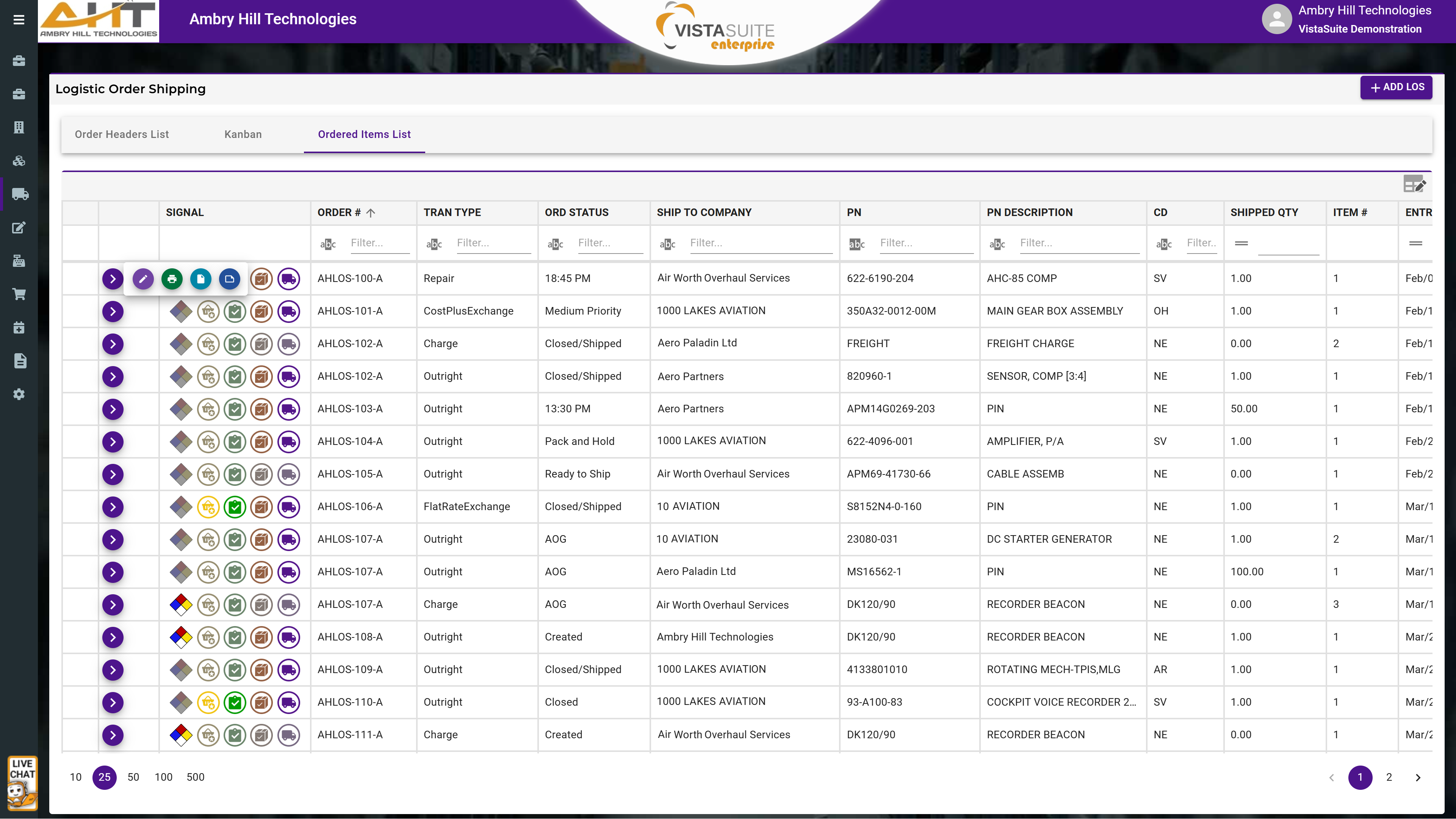

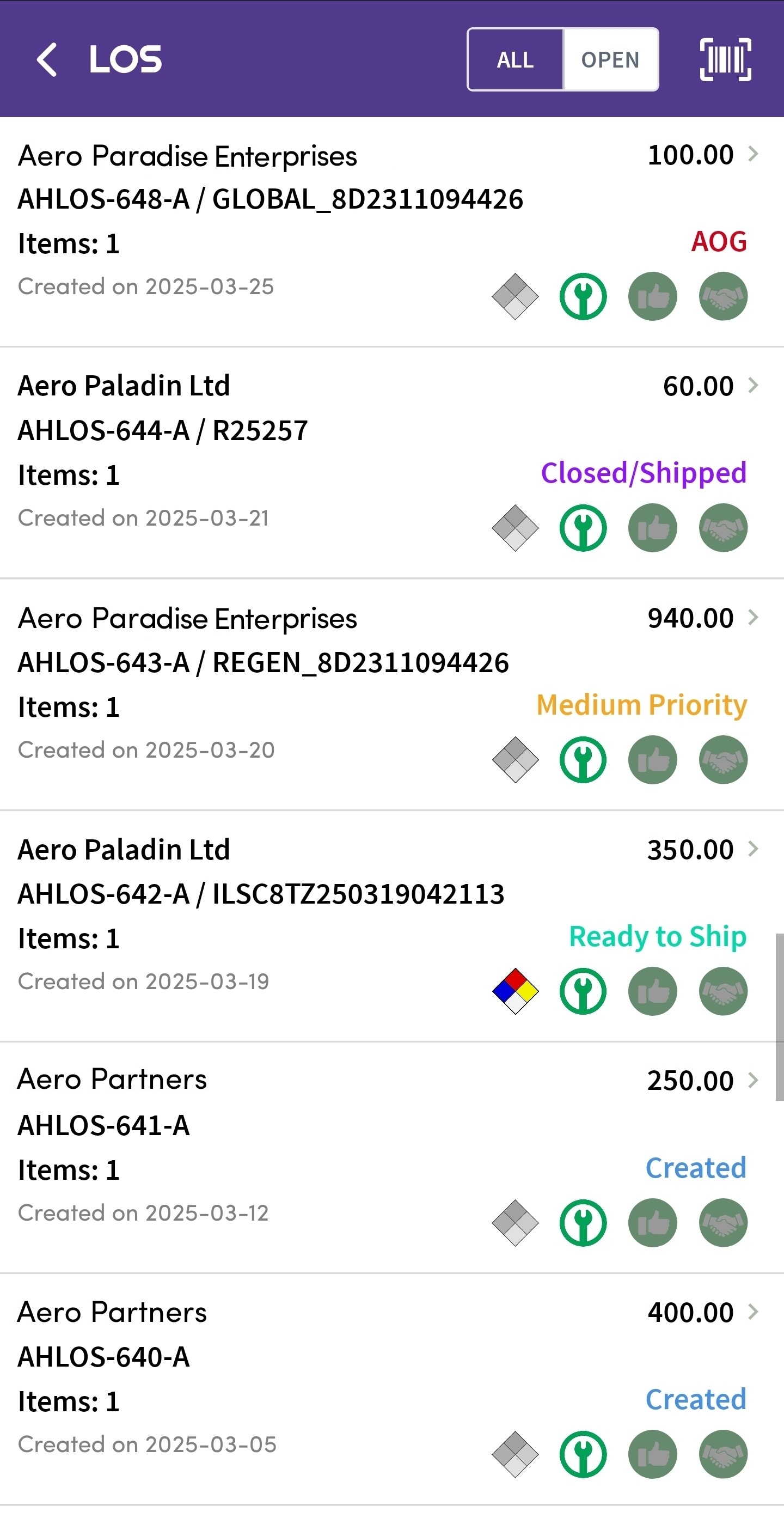

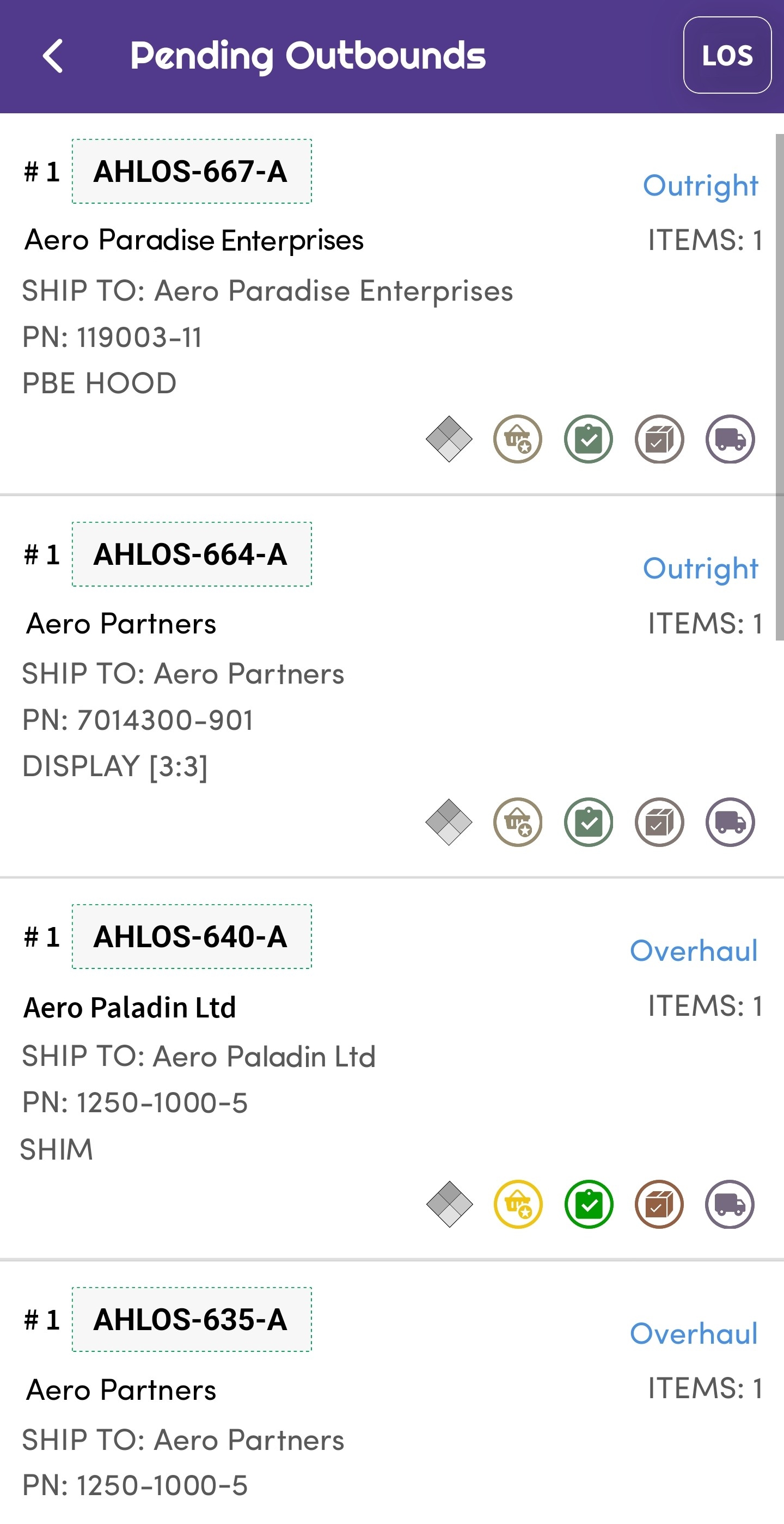

Each LOS record includes a row of visual signal icons to quickly indicate shipment-related statuses of orders and items, such as hazmat involvement, items have been picked, items have been inspected, items have been packed, or if the shipment has been finalized. Customizable columns display shipment status and item-level dispositions, giving teams real-time visibility into outbound progress without opening the full record.

The "Ordered Items List" layout provides a focused list of all items assigned to LOS records, streamlining outbound operations by eliminating the need to manually identify item-level shipping order details. From this view, users can quickly take action to edit item information, print documents, access attachments, or view item-specific notes

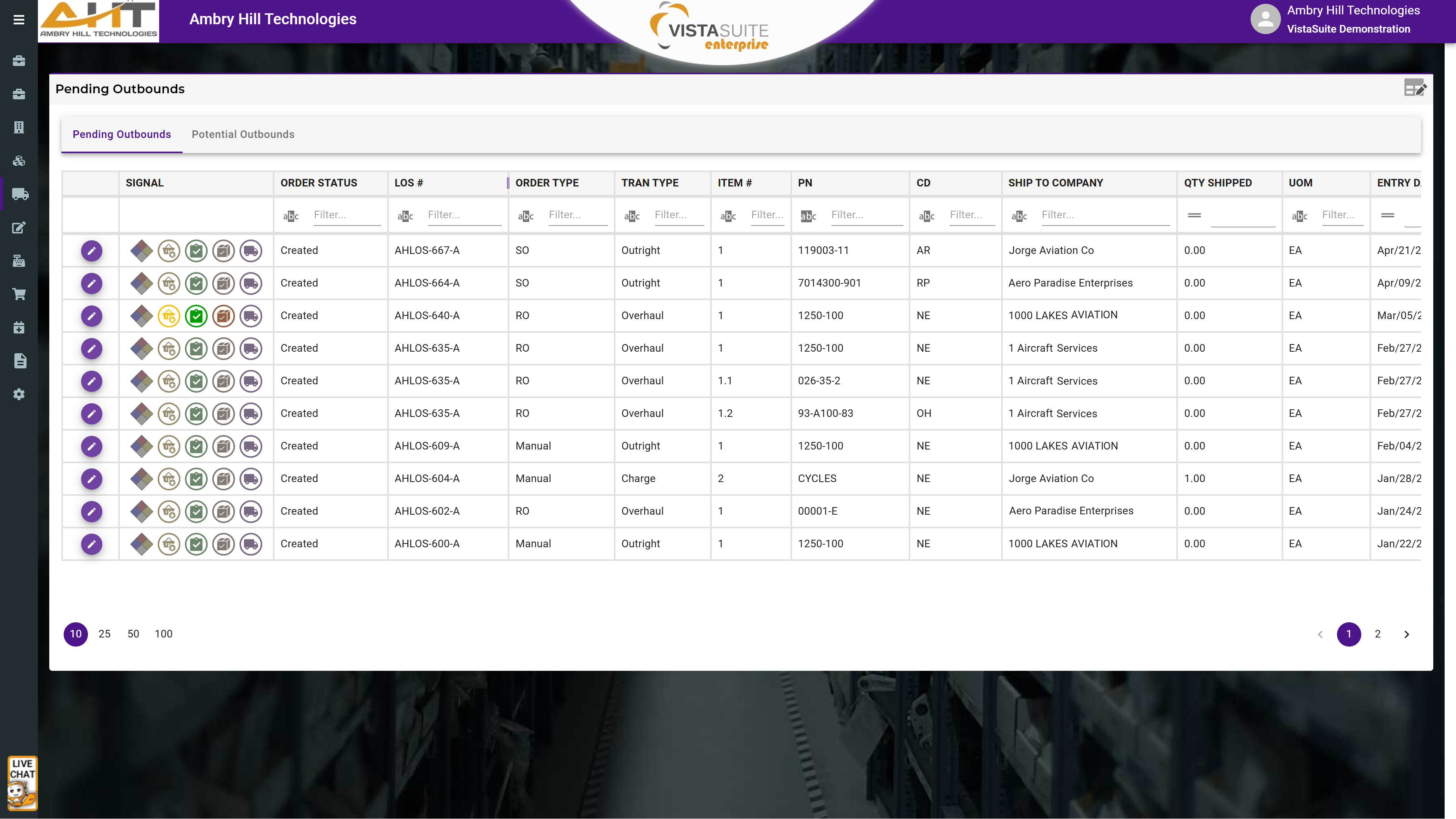

The Pending Shipments view displays all initiated LOS transactions that have not yet been shipped, while the Potential Shipments view surfaces all eligible open sales, repair returns, or exchange transactions across the system that have yet to be assigned to a logistics shipping order. Users can search by order number, part number, transaction type, customer, and more. This innovative approach to outbound shipping management removes the guesswork and reduces time spent switching between modules or tracking down order owners.

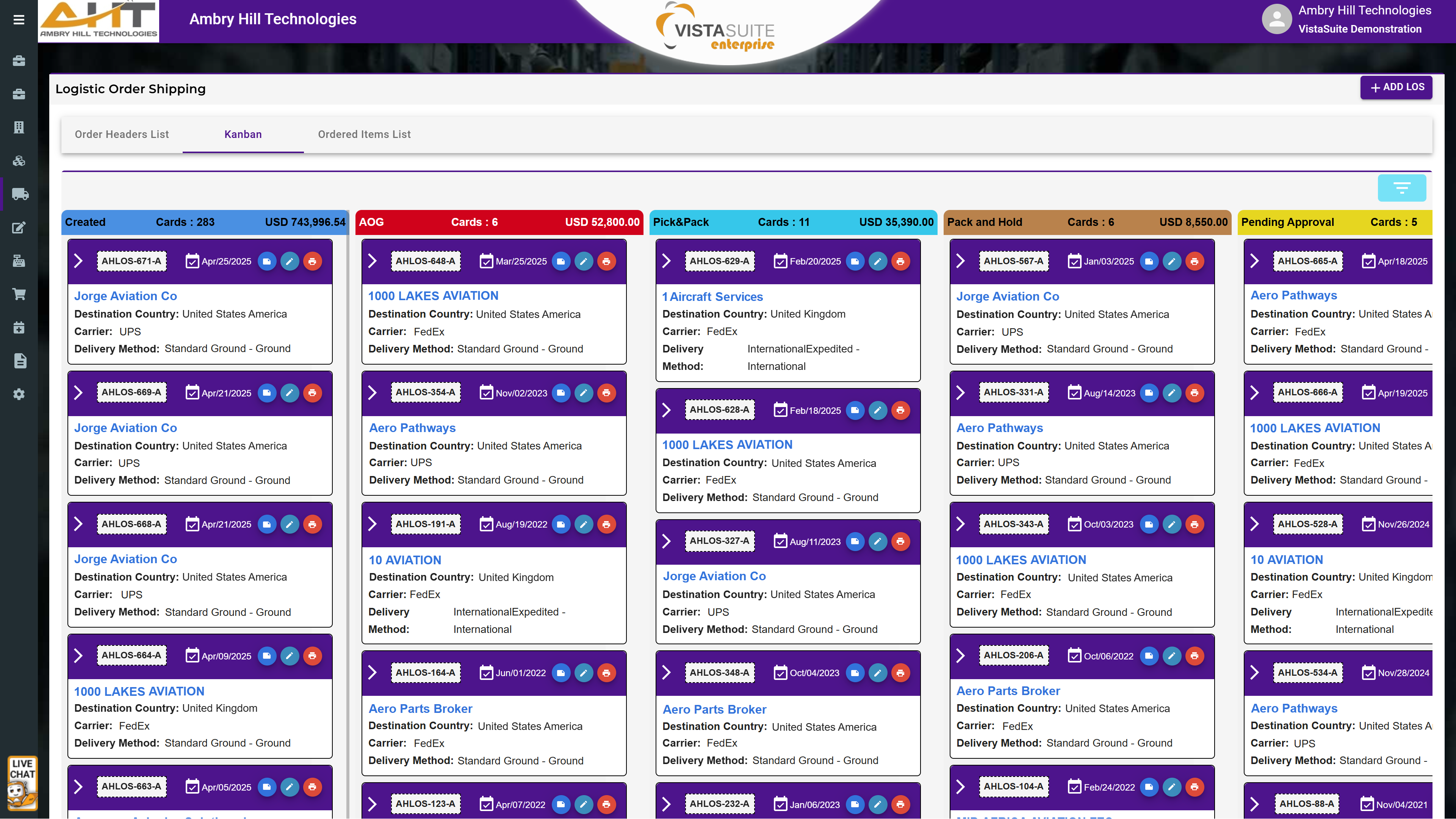

The LOS Kanban layout offers a visual, drag-and-drop workflow for outbound shipments. This layout makes it easy to track the shipping status of each order, identify bottlenecks, and ensure timely processing and dispatch of goods.

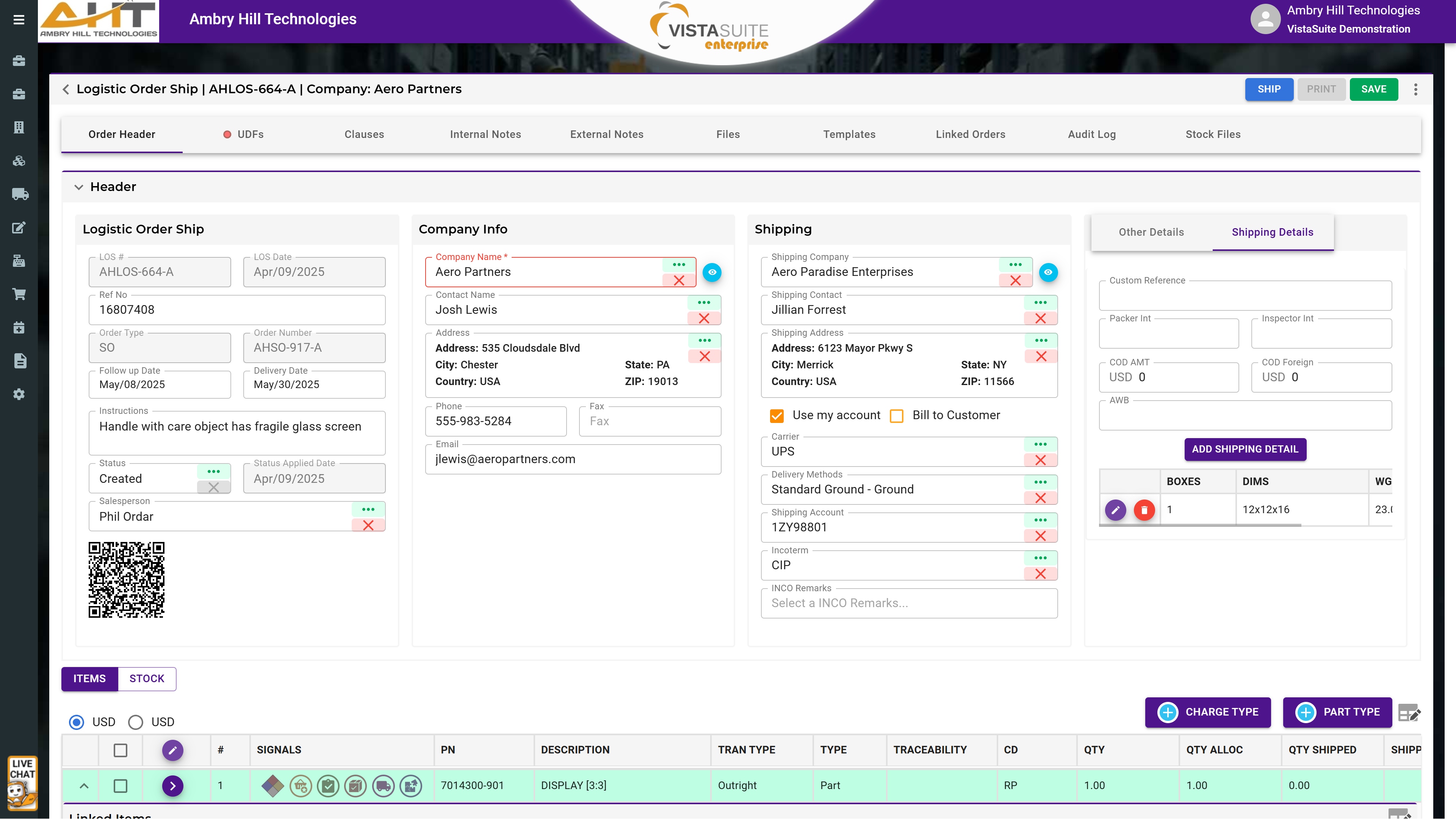

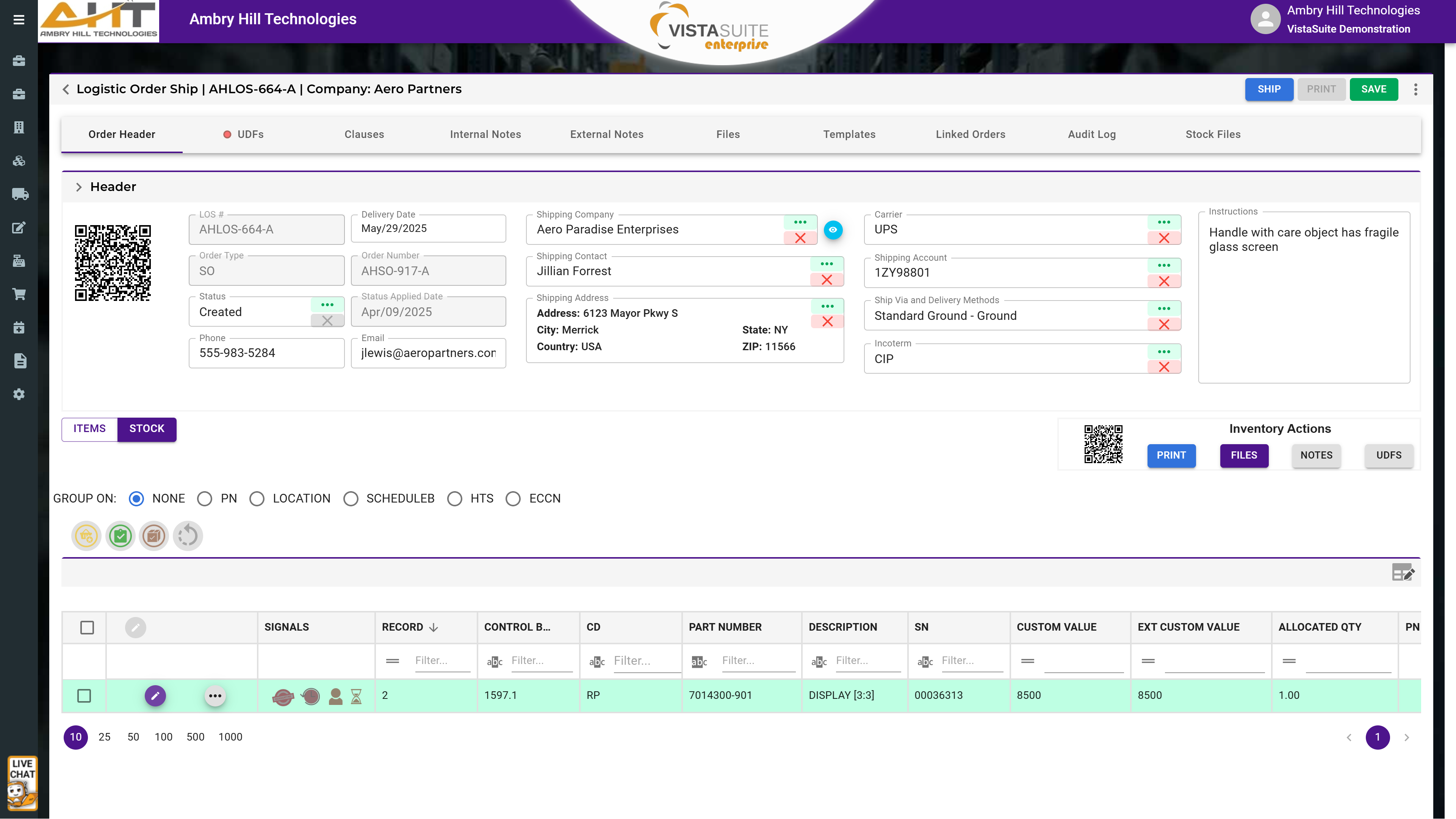

Each LOS record features a well-structured transaction header and tab-based layout, providing intuitive access to all critical shipment details. Line items included in a logistics shipping order are accompanied by visual signals to indicate shipment-related statuses such as hazmat involvement, items have been picked, items have been inspected, items have been packed, if the shipment has been finalized, or includes piece parts.

The LOS transaction interface distinguishes between a general "items" view (representing the ordered or expected items) and a detailed "stock" view (representing the individual inventory records/serialized parts). Manage and track stock through every fulfillment stage (e.g., Picked, Inspected, Packed, and Shipped) using batch actions, filters, and a reset option for maximum flexibility. All activity is logged in the LOS audit log for full accountability.

Outbound Items Report in Logistics Order Shipping (LOS):

The Outbound Items Report provides a detailed, item-level record of all outbound shipments. It includes key data such as part number, quantity, customs value, HTS code, manufacturer, and full ship-to address, along with shipment metadata like LOS number, ship date, carrier, and Incoterms.

Formatted like a spreadsheet for easy filtering and analysis, it supports audit readiness, export compliance, and customer service. Custom layouts are available upon request.

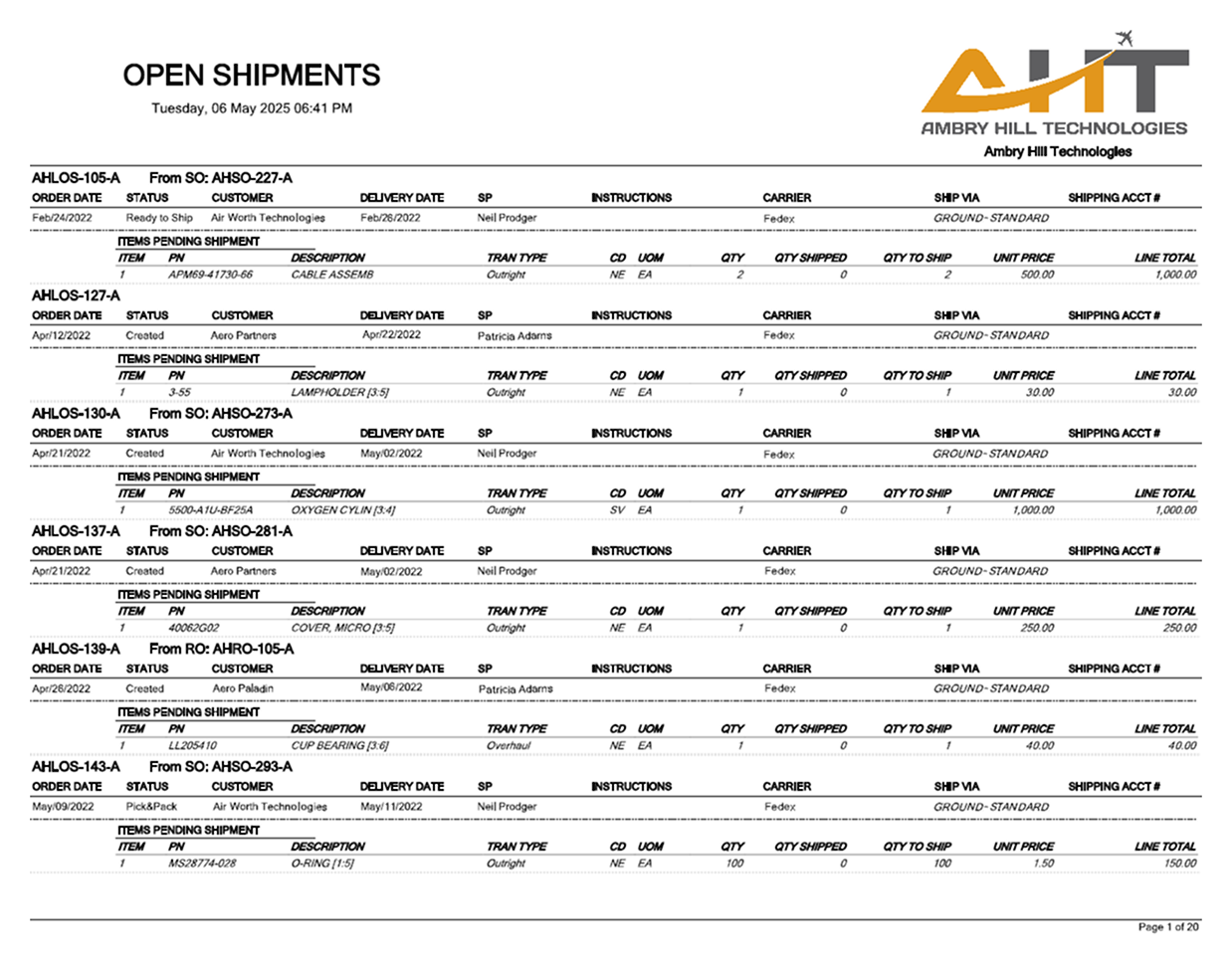

Open Shipments Report: The Open Shipments Report provides a real-time view of all outbound shipment records that have been initiated but are not yet completed. It serves as a working queue for warehouse and logistics personnel, highlighting orders that are prepared for shipment but still pending dispatch or final processing. This report supports proactive shipment management, prevents delays, and ensures nothing is missed during fulfillment. Customized layouts are available as an additional service to better align with unique operational needs or reporting standards.

Authorized Release Certificates: FAA Form 8130, 8130-3 EASA Form 1, CAA Form 1. And TC Form 1 Air Worthiness Approval Tags are prepopulated and printable.

ASA Form 2020 (Landscape & Portrait Orientation): Standardized forms issued by the Aviation Suppliers Association (ASA) to document parts transactions, ensuring compliance with industry best practices for traceability and quality assurance.

ATA 106: A standardized industry form used to document traceability and quality details of aircraft parts, often accompanying transactions to ensure compliance with aviation regulations.

Shipper’s Declaration of Dangerous Goods Certificate: This LOS document is used to certify that hazardous materials included in a shipment are properly classified, packaged, labeled, and declared in full compliance with IATA Dangerous Goods Regulations. It includes essential information such as the hazard class, UN number, packaging details, and handling instructions, along with a signed declaration from the shipper.

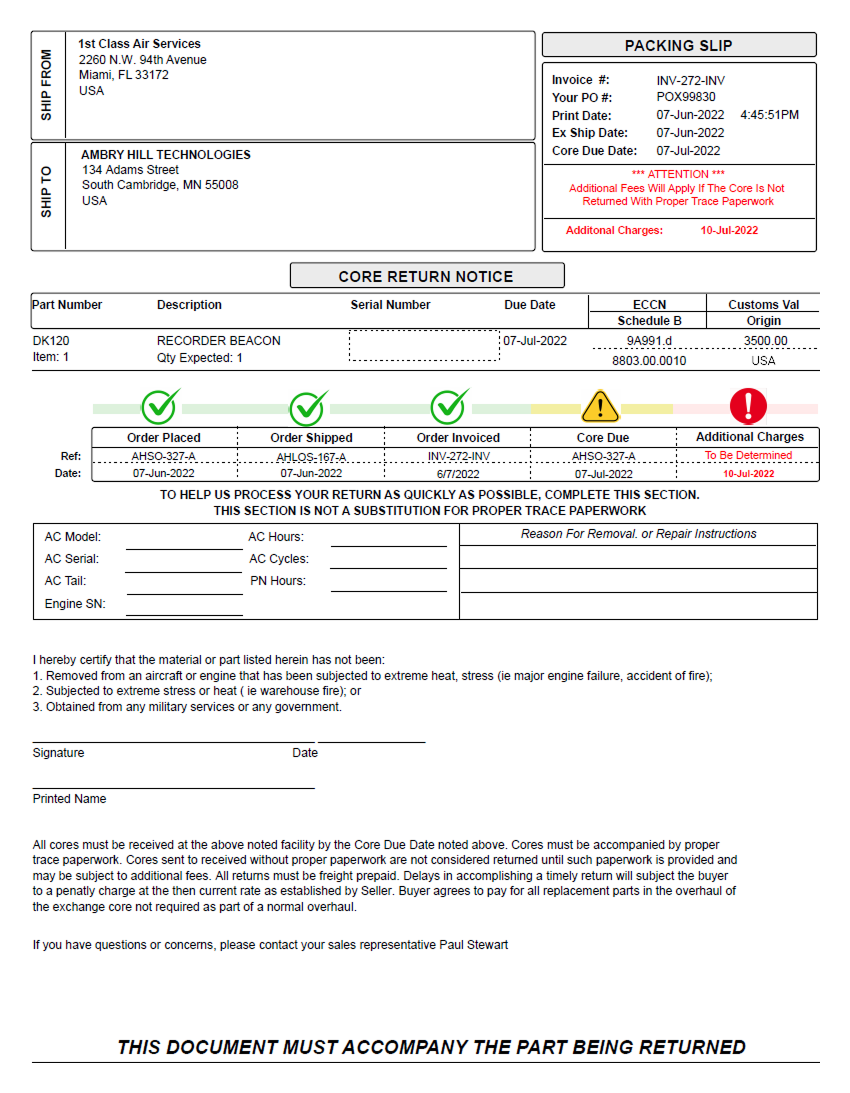

Core Return Pack Slip: The Core Return Pack Slip is a document generated by the Logistics Order Shipping (LOS) module to accompany the shipment of a part that requires a core return. It provides clear instructions and reference details for the recipient to return the used or repairable core component. Typically included in the outbound shipment, the slip stays with the new or overhauled part and serves as both a return authorization and tracking reference when the core is sent back. This document helps streamline the reverse logistics process, reduce delays in core returns, and ensure proper matching of returned cores to original transactions.

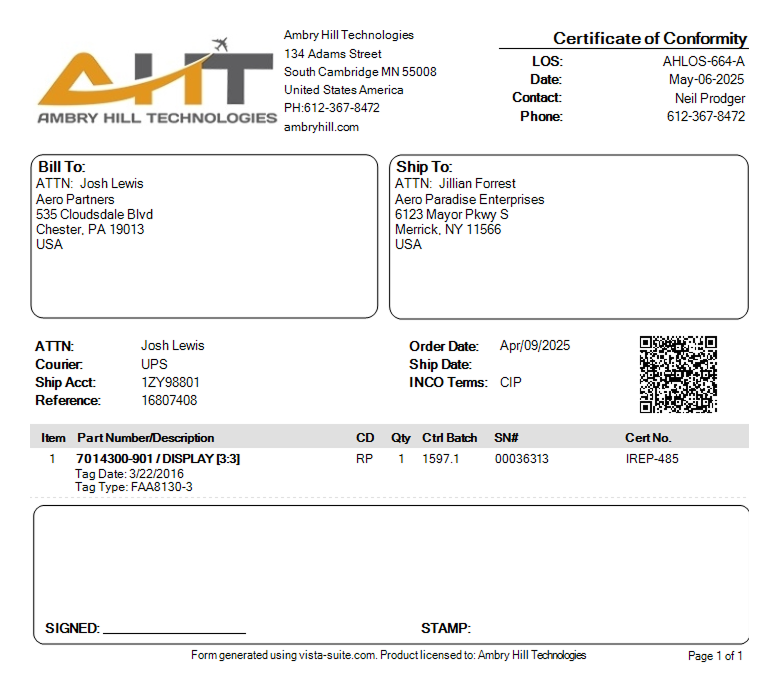

C of C Form (Certificate of Conformance): The Certificate of Conformance is a document certifying that a part meets the required specifications and was produced in accordance with industry and regulatory standards. It is typically included with shipments to assure the receiving party that the part is airworthy and compliant. Having a valid C of C on file helps avoid costly delays during inspections or audits and provides a clear paper trail for traceability and accountability.

Customs Invoice Document: The Customs Invoice, generated by the Logistics Order Shipping (LOS) module, is a required document for international shipments. It provides customs authorities with all the necessary details to assess duties, taxes, and ensure the legal movement of goods across borders. This includes information such as item descriptions, quantities, declared value, country of origin, HTS codes, Incoterms, and full shipper and consignee details. The Vista-Suite Enterprise LOS system automatically pulls this data from the corresponding order, reducing manual entry and minimizing errors. By standardizing this critical document, the system helps shippers maintain compliance with global trade regulations and avoid delays in customs clearance.

Customs Part Certificate of Origin: When exporting goods internationally, shippers are often required to provide a Certificate of Origin to verify the country where the product was manufactured. This document is used by customs authorities in the destination country to determine eligibility for trade agreements, duty rates, or import restrictions. The Logistics Order Shipping (LOS) module includes a pre-built Certificate of Origin that automatically pulls relevant data from the shipment record, helping with accurate documentation and supporting cross-border compliance.

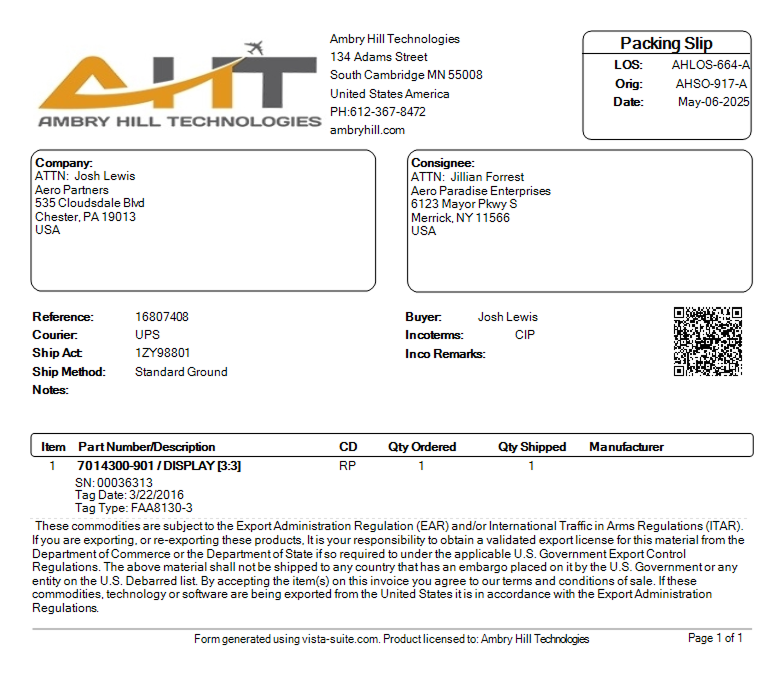

Pack Slip: Included with shipments, the Pack Slip details the contents of the package for verification upon receipt. For example, when an MRO facility receives a shipment of parts, the receiving personnel uses the pack slip to quickly confirm that all expected components are present before moving them into inventory. This helps your team identify missing or incorrect items immediately and provides clear documentation when escalating shipping or supplier errors.

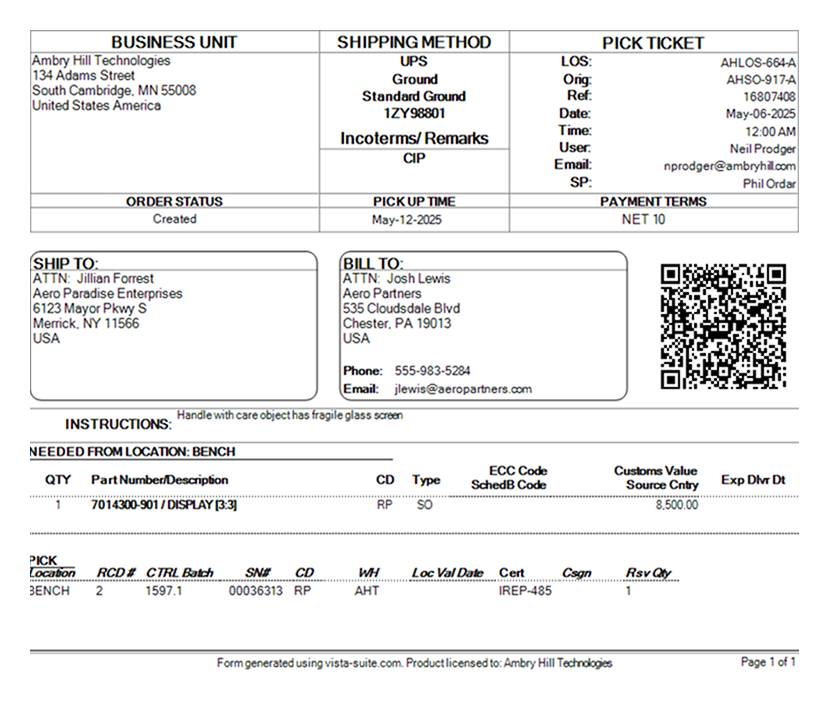

Pick Ticket: This internal document informs warehouse staff on which items to retrieve for order fulfillment. It clearly lists part numbers, quantities, and storage locations to streamline the picking process and reduce errors. A well-prepared pick ticket helps teams move faster and with greater confidence, especially when time-sensitive orders are in play.

Repair Order Form (LOS): The Repair Order Document is a standardized, professional form generated within the LOS application to accompany shipments sent to suppliers or repair vendors. It clearly outlines all relevant repair instructions, delivery and payment terms, part details, and pricing agreements. The document includes both outbound and return address information to ensure accurate routing and traceability throughout the repair process.

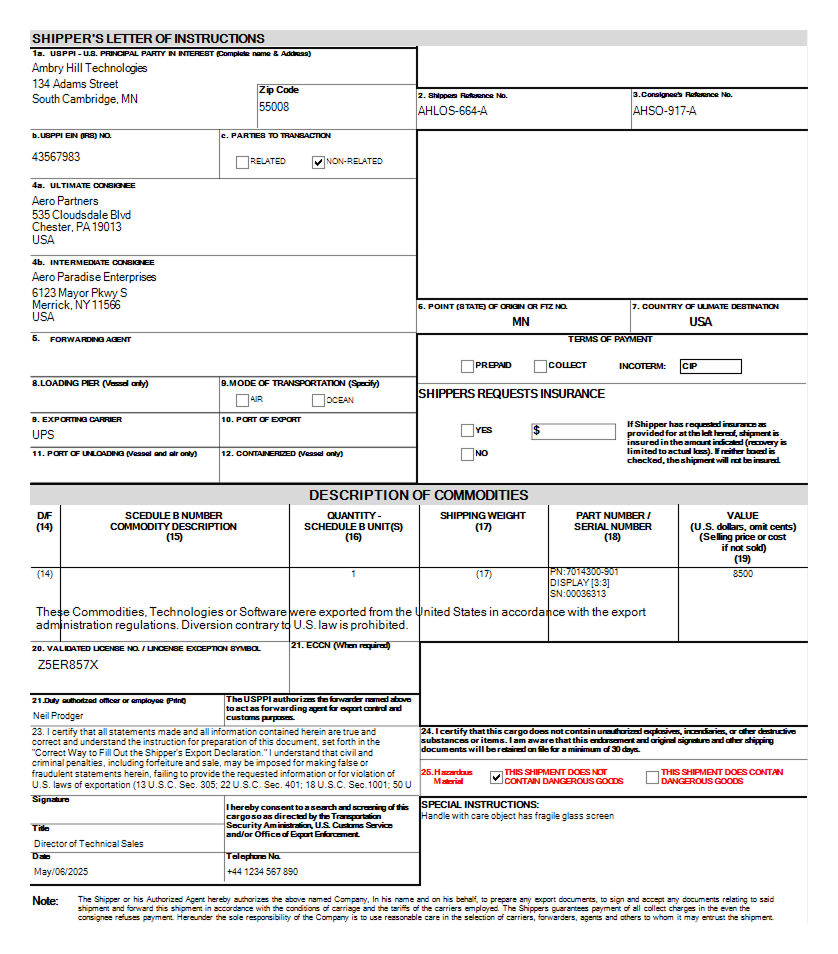

Shipper's Letter of Instructions: The Shipper’s Letter of Instructions (SLI), generated through the Logistics Order Shipping (LOS) module, is used to communicate detailed shipping requirements to a freight forwarder or logistics provider. It includes instructions such as how and when to ship the goods, preferred carriers, insurance needs, handling requirements, and references to required documents like the commercial invoice or export licenses.

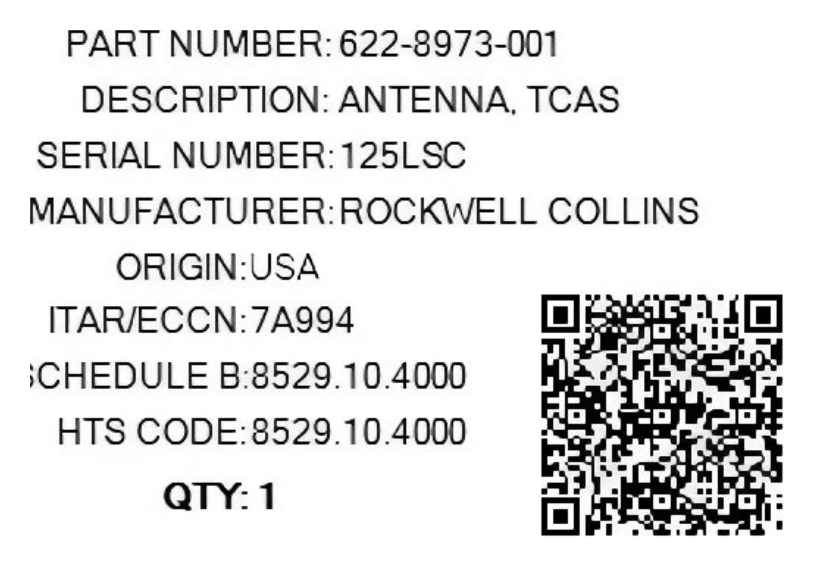

Shipping Label: Essential compliance information and manufacturer traceability are embedded into a single, easy-to-read label. This isn’t a typical label; it’s a built-in quality and compliance tool that enhances every shipment.

Unlike generic ERP-generated labels, this format includes critical export and customs data, supports serialized inventory management, and includes QR codes to quickly retrieve the corresponding LOS record through the Vista-Suite Enterprise mobile application.

The Open Shipments Report provides a real-time view of all outbound shipment records that have been initiated but are not yet completed. It serves as a working queue for warehouse and logistics personnel, highlighting orders that are prepared for shipment but still pending dispatch or final processing. This report supports proactive shipment management, prevents delays, and ensures nothing is missed during fulfillment. Customized layouts are available as an additional service to better align with unique operational needs or reporting standards.

The Core Return Pack Slip is a document generated by the Logistics Order Shipping (LOS) module to accompany the shipment of a part that requires a core return. It provides clear instructions and reference details for the recipient to return the used or repairable core component. Typically included in the outbound shipment, the slip stays with the new or overhauled part and serves as both a return authorization and tracking reference when the core is sent back. This document helps streamline the reverse logistics process, reduce delays in core returns, and ensure proper matching of returned cores to original transactions.

The Certificate of Conformance is a document certifying that a part meets the required specifications and was produced in accordance with industry and regulatory standards. It is typically included with shipments to assure the receiving party that the part is airworthy and compliant. Having a valid C of C on file helps avoid costly delays during inspections or audits and provides a clear paper trail for traceability and accountability.

Included with shipments, the Pack Slip details the contents of the package for verification upon receipt. For example, when an MRO facility receives a shipment of parts, the receiving personnel uses the pack slip to quickly confirm that all expected components are present before moving them into inventory. This helps your team identify missing or incorrect items immediately and provides clear documentation when escalating shipping or supplier errors.

This internal document informs warehouse staff on which items to retrieve for order fulfillment. It clearly lists part numbers, quantities, and storage locations to streamline the picking process and reduce errors. A well-prepared pick ticket helps teams move faster and with greater confidence, especially when time-sensitive orders are in play.

The Shipper’s Letter of Instructions (SLI), generated through the Logistics Order Shipping (LOS) module, is used to communicate detailed shipping requirements to a freight forwarder or logistics provider. It includes instructions such as how and when to ship the goods, preferred carriers, insurance needs, handling requirements, and references to required documents like the commercial invoice or export licenses.

Essential compliance information and manufacturer traceability are embedded into a single, easy-to-read label. This isn’t a typical label; it’s a built-in quality and compliance tool that enhances every shipment.

Unlike generic ERP-generated labels, this format includes critical export and customs data, supports serialized inventory management, and includes QR codes to quickly retrieve the corresponding LOS record through the Vista-Suite Enterprise mobile application.

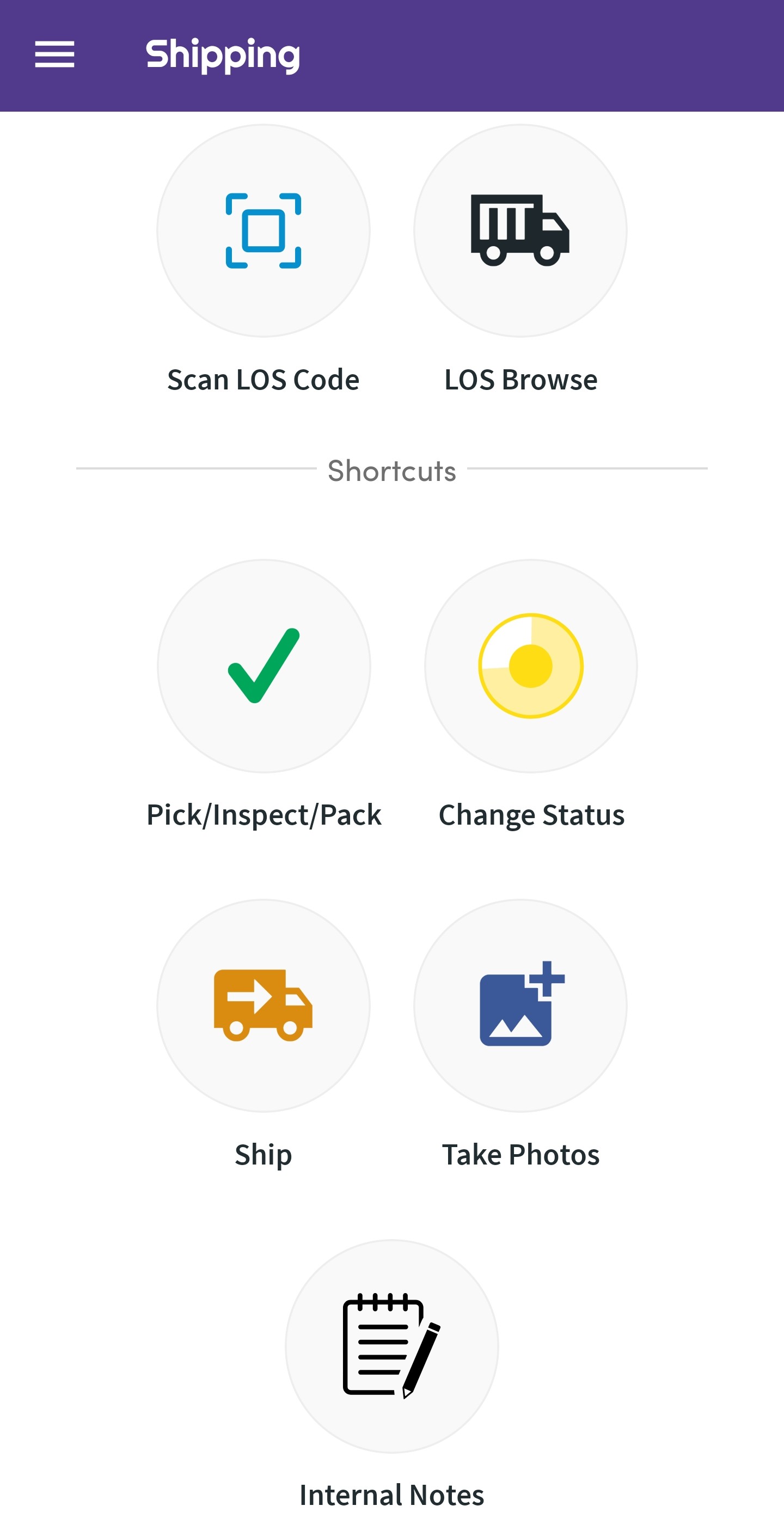

Quickly locate any Logistics Order Shipment (LOS) record by scanning a LOS QR code. This simple, yet valuable capability minimizes manual search errors and speeds up shipping workflows from the start.

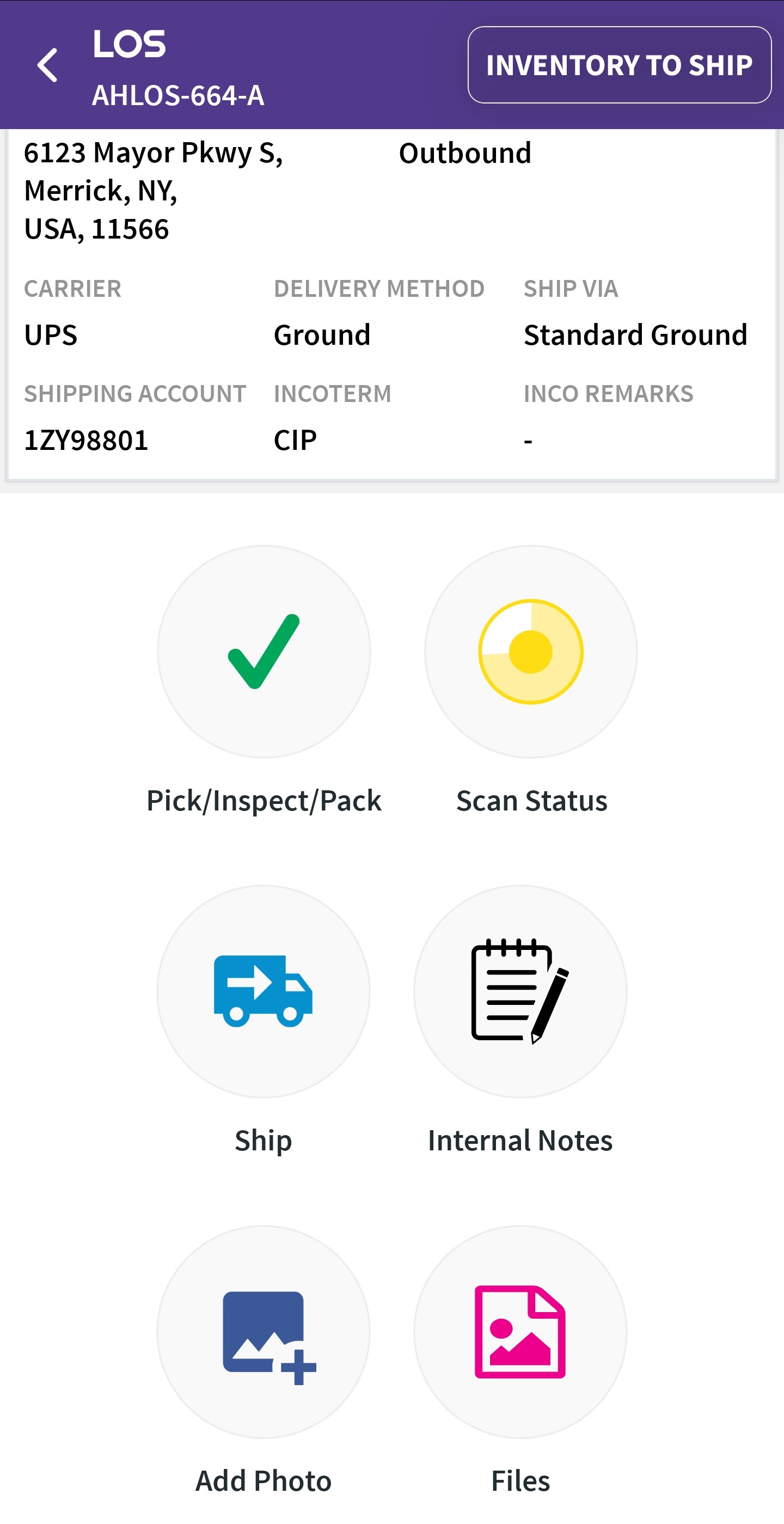

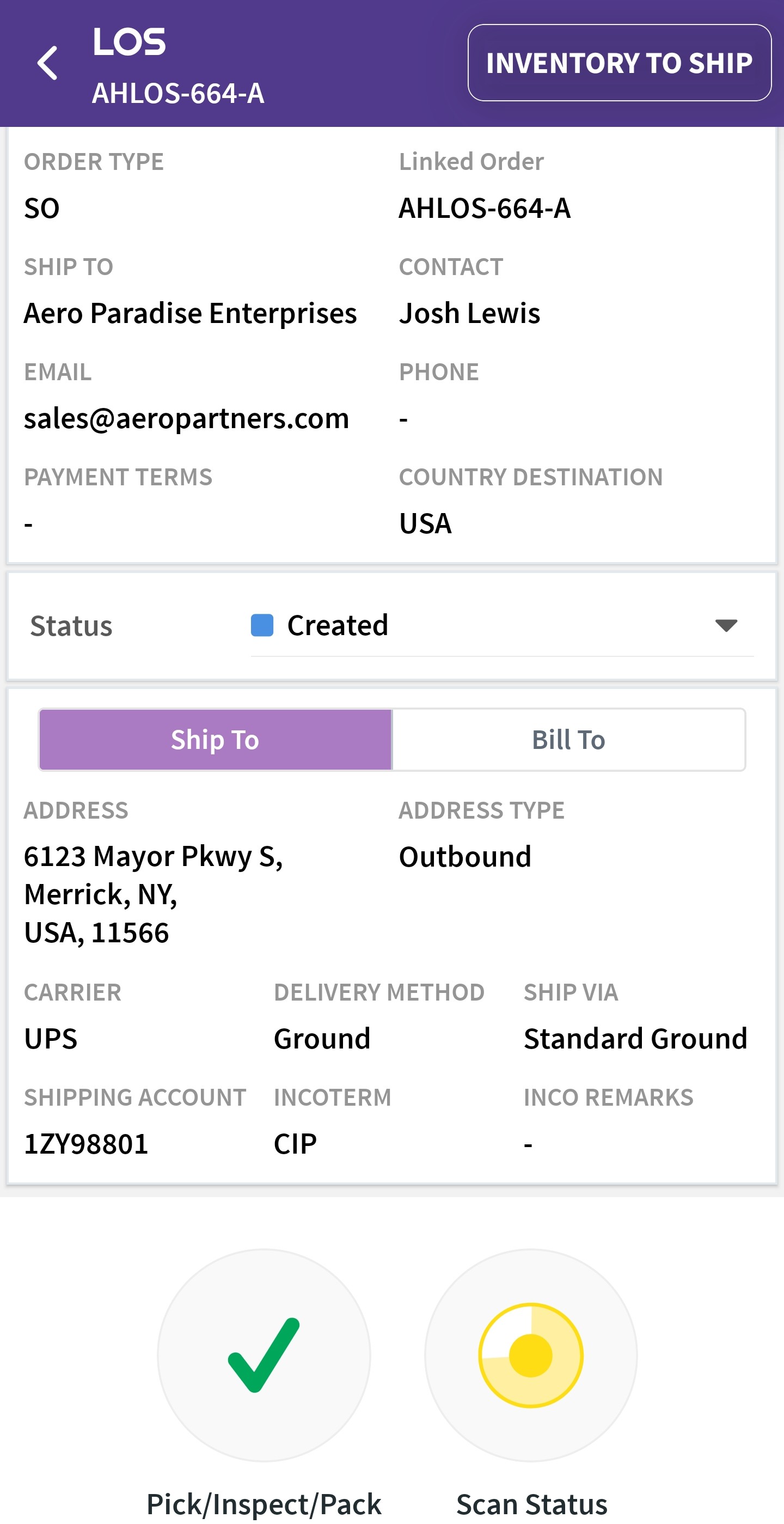

Access comprehensive details for each shipment, including customer information, addresses, and shipping terms. Centralizes order information for improved accuracy across shipping operations.

Get a live view of allocated and available inventory. Details include the serial number, control batch, and warehouse location for accurate picking and efficient order fulfillment.

Easily browse all orders, or just the open ones, complete with status and priority indicators that allow your team to swiftly prioritize, track, and respond to order requirements.

Check shipments queued for outbound processing at a glance. Effortlessly manage priorities and ensure timely shipments to customers.

All critical shipping workflow actions are consolidated into a single accessible interface, enabling users to advance shipments, update statuses, attach documentation, and communicate

We will respond to you within minutes